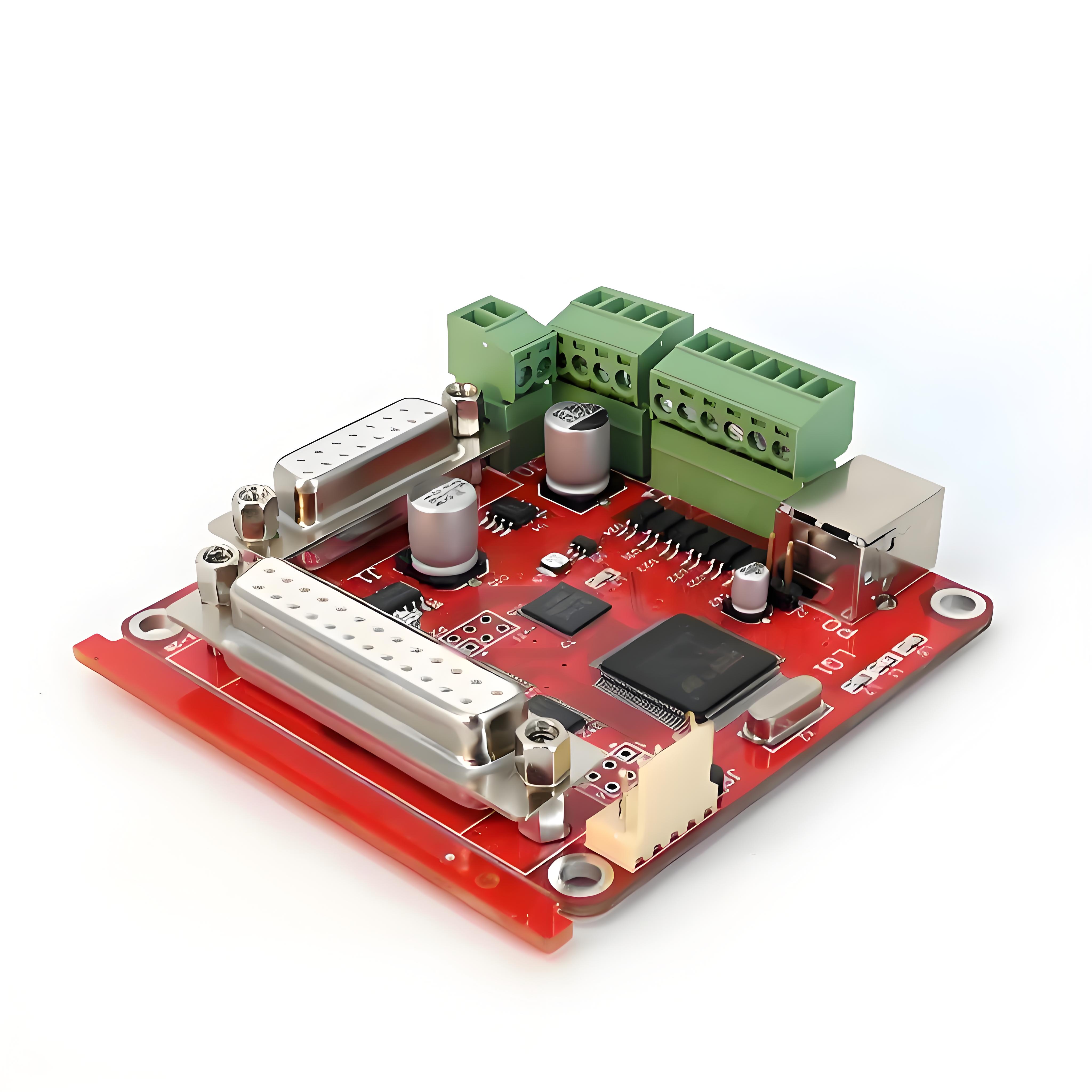

Industrial PCBA Manufacturer - Tecoo EMS

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Industrial Printed Circuit Board Assembly (PCBA) serves as a core component of electronic manufacturing and is a critical infrastructure for industries such as industrial automation, smart manufacturing, and energy management. With the rapid development of Industry 4.0, the Internet of Things (IoT), and artificial intelligence (AI) on a global scale, the market demand and technical requirements for industrial PCBA continue to evolve. This article provides an in-depth analysis of the development paths and opportunities for industrial PCBA manufacturers from multiple perspectives, including industry status, technological drivers, market demand, competitive landscape, and future challenges.

I. Current State of the Industrial PCBA Industry and Market Drivers

1. Market Size and Growth Drivers

According to industry reports, the global PCBA market size is projected to reach 147.5 billion USD by 2035, with a compound annual growth rate (CAGR) of 4.7% from 2025 to 2035.

The industrial sector serves as the core growth engine, primarily driven by the following areas:

Industrial Automation and Smart Manufacturing: There is a surging demand for high-reliability PCBA in industrial robots, PLC controllers, sensors, and other equipment.

New Energy Vehicles and Energy Management: The battery management systems (BMS) of electric vehicles, charging stations, and smart grid equipment are driving customised PCBA demand.

5G and Industrial Internet of Things: The deployment of 5G base stations and industrial communication modules requires high-frequency, high-speed PCBA support.

2. Industrial Chain Structure and Technical Barriers

Industrial PCBA manufacturing involves upstream materials (such as high-frequency copper-clad laminates and connectors), midstream SMT (surface mount technology) and testing, and downstream end applications. Its technical barriers primarily manifest in:

High-Precision Processes: Industrial equipment imposes stringent requirements on PCBA for high-temperature resistance, interference resistance, and long service life.

Customisation capabilities: Different industrial scenarios (such as automated production lines and energy equipment) require tailored design solutions.

II. Industry Upgrades Driven by Technology

1. Intelligent and automated production

Industrial PCBA manufacturers are leveraging Industry 4.0 technologies to comprehensively upgrade production processes:

AI quality inspection systems: Defect detection technology based on machine vision reduces false positive rates to below 0.1%, improving yield rates.

Flexible production lines: Modular design enables rapid switching between product models to meet small-batch, multi-variety order demands.

Predictive maintenance: IoT sensors monitor equipment status in real time to reduce downtime risks.

2. Material and Process Innovation

High-performance substrates: Materials such as polytetrafluoroethylene (PTFE) and high-frequency ceramic substrates are used in high-frequency, high-speed PCBA to meet 5G and radar system requirements.

3D printing technology: Experimentally applied to rapid prototyping of complex-structured PCBA to shorten the R&D cycle.

3. Reliability and environmental standards

Industrial applications have much higher reliability requirements for PCBA than consumer electronics. Manufacturers must meet these requirements through the following measures:

Lead-free soldering and environmentally friendly processes: Compliant with RoHS and REACH regulations to reduce harmful substance emissions.

Three-proof treatment: Applying moisture-proof, dust-proof, and corrosion-resistant coatings to withstand harsh industrial environments.

III. Market Demand and Segment Analysis

1. Core Application Scenarios

Industrial Automation: Servo drives, industrial robot controllers, and other devices rely on high-density PCBA for precise control.

Energy and Power: Smart meters and photovoltaic inverters require PCBA solutions capable of withstanding high voltage and electromagnetic interference.

Medical Equipment: Medical imaging equipment and surgical robots have extremely high requirements for PCBA electromagnetic compatibility (EMC) and safety.

2. Regional Market Characteristics

Asia-Pacific Dominance: The Pearl River Delta and Yangtze River Delta regions in China are home to global leading contract manufacturers such as Foxconn and Luxshare Precision, accounting for over 60% of the market share.

High-end demand in Europe and the United States: Germany's Industry 4.0 and the United States' Industrial Internet are driving growth in high-end customised PCBA orders.

IV. Competitive Landscape and Key Players

1. Differentiation between international giants and domestic companies

International companies: Hon Hai Precision (Foxconn), Flex, Jabil, Tecoo and others dominate the high-end market with their scale advantages and global footprint.

Domestic Companies: Chinese firms like Shenzhen South Circuit and Huatong Electronics are breaking into the automotive electronics and communications sectors through technological upgrades..

2. Differentiated Competition Strategies

Technological Specialisation: Leading companies focus on high-value-added products like HDI (High-Density Interconnect) boards and rigid-flex boards.

Vertical Integration: Some manufacturers are expanding upstream to develop chip-level packaging technologies to reduce costs..

V. Challenges and Response Strategies

1. Industry Pain Point Analysis

Technical Talent Shortage: Insufficient supply of high-end process engineers and AI algorithm experts is hindering innovation speed.

Supply Chain Volatility: Geopolitical risks are causing instability in the supply of critical raw materials (such as high-end copper-clad laminates).

Cost Pressure: Rising raw material prices and customer price pressures are compressing profit margins, making it difficult for small and medium-sized manufacturers to survive..

2. Breakthrough Strategies

Industry-Academia-Research Collaboration: Collaborate with universities to cultivate technical talent and establish joint laboratories to overcome technical bottlenecks.

Supply Chain Diversification: Expand into emerging manufacturing hubs in Southeast Asia and Eastern Europe to mitigate geopolitical risks.

Service Transformation: Offer end-to-end lifecycle services from design to maintenance to enhance customer loyalty.

VI. Future Outlook: Technology Convergence and Market Opportunities

1. Emerging Technology Enablement

AIoT Integration: PCBA will deeply integrate edge computing chips to enable localised data processing and real-time responses.

Flexible Electronics: Foldable and wearable industrial devices will drive a surge in demand for flexible PCBA.

2. Sustainable Development Trends

Circular Economy Model: Establish a PCBA recycling system and reduce resource waste through precious metal extraction technology.

Green Manufacturing Certification: Obtain international certifications such as UL and TÜV to enhance export competitiveness.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.