The Key Role of SMT Processing in Medical Device Manufacturing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

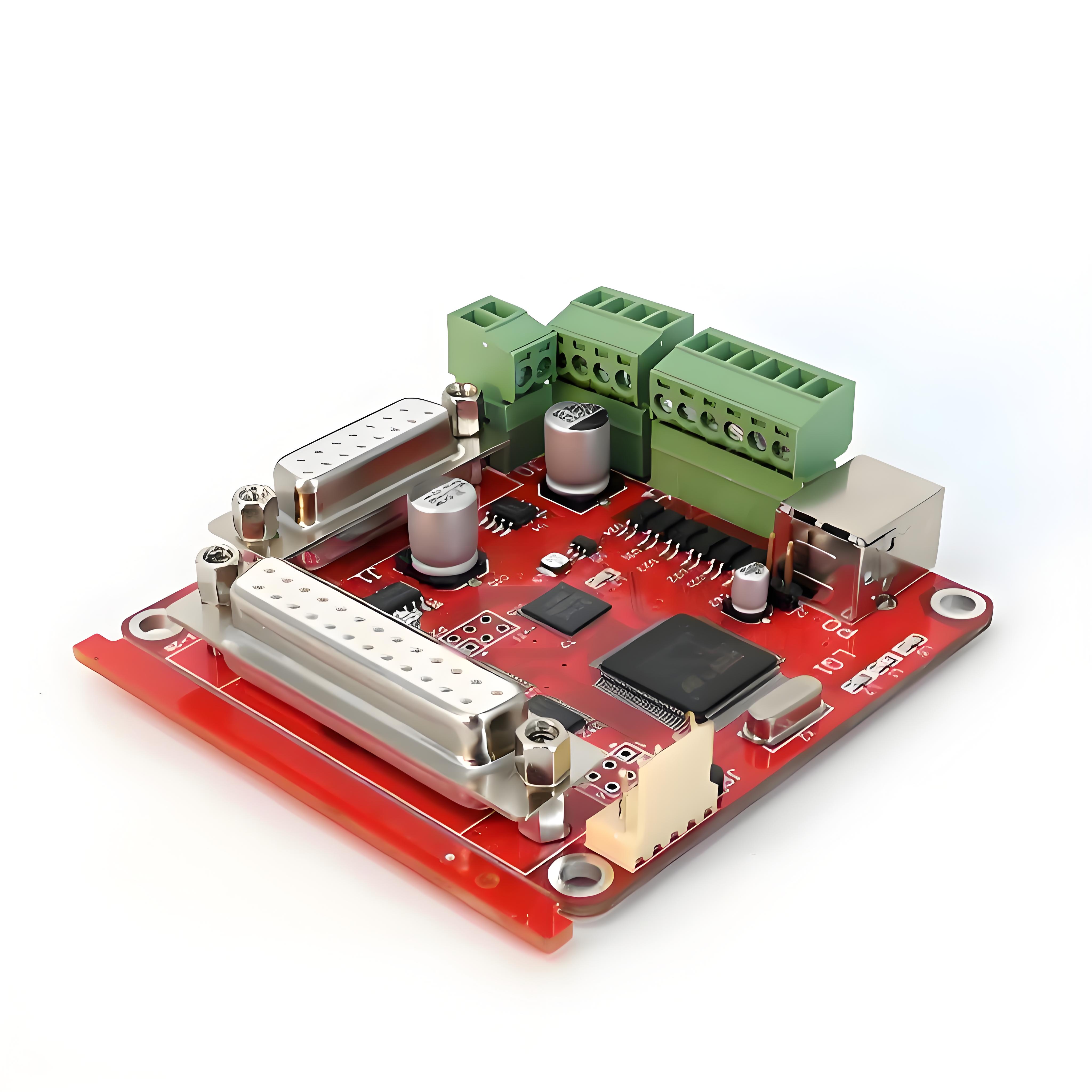

The Critical Role of SMT Processing in Medical Device Manufacturing As technology continues to advance, the demand for precision manufacturing technologies in the medical device manufacturing industry is growing rapidly.

Among various manufacturing technologies, Surface Mount Technology (SMT) plays a critical role in medical device manufacturing due to its high precision, efficiency, and reliability.

This article will detail the importance of SMT processing in medical device manufacturing from the following aspects.

1. Improving Production Efficiency SMT processing utilises automated production lines, employing precise placement equipment to quickly and accurately mount electronic components onto PCB boards.

Compared to traditional manual soldering, SMT processing significantly enhances production efficiency and reduces labour costs.

In medical device manufacturing, time is of the essence, and efficient SMT processing technology helps save precious time in patient rescue efforts.

2. High-quality product reliability SMT processing employs advanced testing equipment to enforce strict quality control at every production stage.

From component selection, PCB board manufacturing to final product testing, each step is inspected using precision instruments and stringent standards.

This rigorous quality control enhances the stability and reliability of medical devices, providing robust safety assurance for patients.

3. Achieving high-precision manufacturing Medical devices have extremely high precision requirements, and even minor errors can affect device performance.

SMT processing technology, through high-precision placement equipment and advanced production processes, can achieve micron-level placement precision, meeting the high-precision manufacturing requirements of medical devices.

This high-precision manufacturing technology provides a solid foundation for the stable performance and reliability of medical devices.

4. Promoting technological innovation The continuous development and innovation of SMT processing technology have opened up new possibilities for medical device manufacturing.

As new electronic components emerge, SMT processing technology can swiftly adapt and apply these new technologies, driving technological innovation in medical devices.

This technological innovation not only enhances device performance but also provides additional momentum for the development of the medical field.

5. Reducing Production Costs Although the initial investment in SMT processing equipment is relatively high, its high production efficiency and strict quality control significantly reduce production costs over the long term.

SMT processing technology also minimises raw material waste and labour costs, further improving production efficiency.

This cost advantage enables medical device manufacturers to maintain competitiveness in the highly competitive market.

6. Adapting to Market Demands As medical technology continues to advance, the demand for medical devices has become increasingly diverse and personalised.

SMT processing technology can quickly adapt to changes in market demand by adjusting production line configurations and process flows to produce medical devices of different specifications and functions.

This flexibility enables medical device manufacturers to meet diverse market demands and gain a larger market share.

SMT processing plays a crucial role in medical device manufacturing.

It not only enhances production efficiency, ensures high-quality products, achieves high-precision manufacturing, promotes technological innovation, and reduces production costs, but also adapts to changes in market demand.

With the continuous advancement of technology and the rapid development of the medical field, SMT processing technology will play an increasingly important role in medical device manufacturing, contributing significantly to human health and the development of the medical industry.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.