The Difference Between PCB and PCBA

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

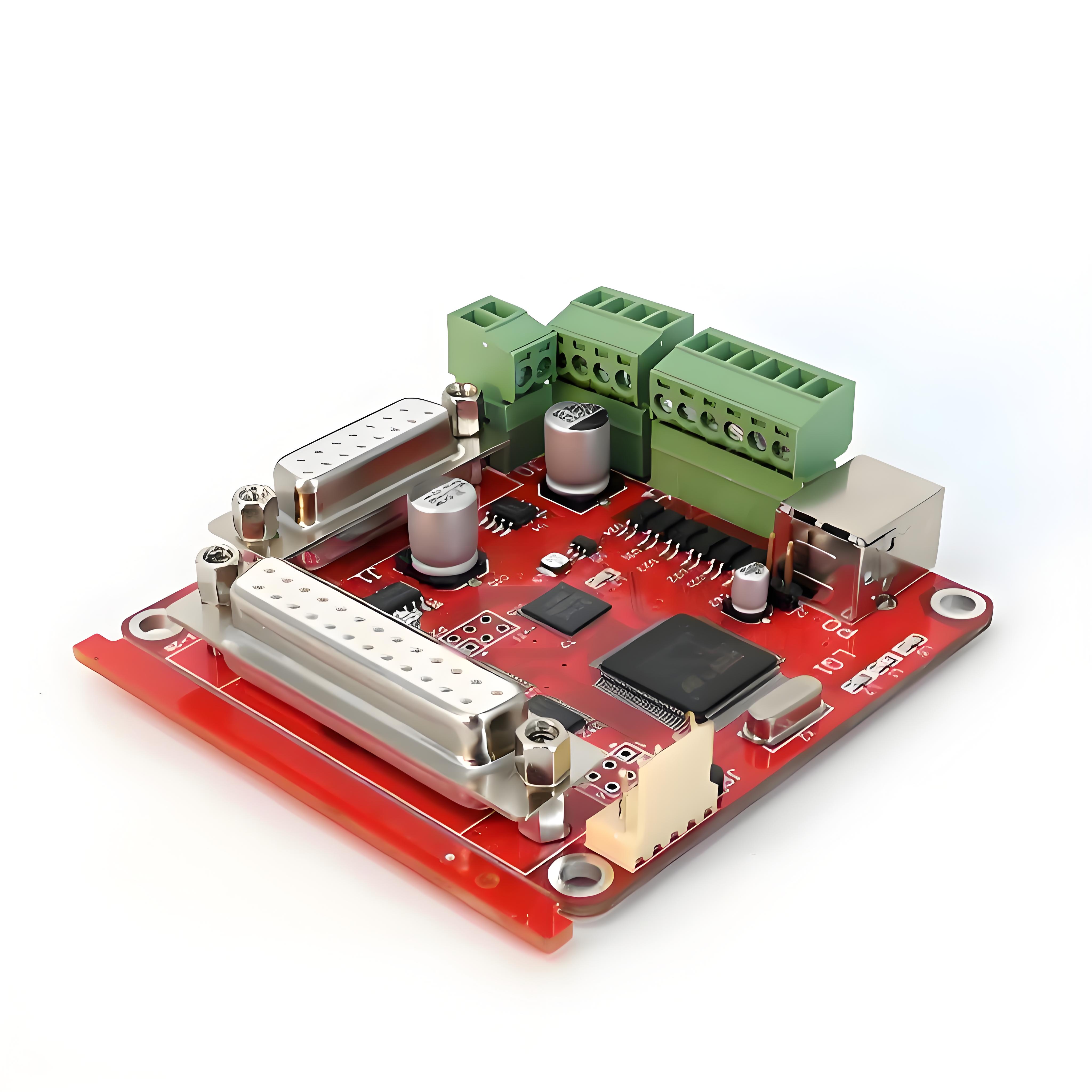

The Difference Between PCB and PCBA In the electronics manufacturing industry, PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) are two terms that are frequently mentioned.

Although both are related to circuit boards, they differ significantly in terms of function, manufacturing process, and final product form.

Below, we will delve into the differences between PCB and PCBA in detail.

I. Definition and Function 1. PCB (Printed Circuit Board) - Definition: A PCB is a substrate used for electrical connections between electronic components. It is created by etching, drilling, and copper plating processes on an insulating base material to form conductive circuit patterns.

- Function: A PCB primarily serves as a support and electrical connection for electronic components, acting as their carrier.

It does not contain any active or passive components itself and is merely a basic framework.

2. PCBA (Printed Circuit Board Assembly) - Definition: PCBA is the process of assembling electronic components onto a PCB using SMT (Surface Mount Technology) or THT (Through-Hole Technology) to form a circuit board assembly with specific functions.

- Function: PCBA includes the PCB and all necessary electronic components, which work together to achieve the predefined functions of the circuit board.

PCBA is the core component of electronic products, directly determining the product's performance and functionality.

II. Manufacturing Process 1. PCB Manufacturing Process - Design: PCB layout design based on the circuit schematic diagram.

- Base Material Production: Using materials such as copper foil, insulating materials, and prepreg to produce the PCB base material.

- Etching: Removing unnecessary copper foil sections from the base material via chemical or physical methods to form conductive circuit patterns.

- Drilling: Drill holes in the PCB for connecting different layers or installing components.

- Copper Plating: Apply a layer of copper inside the holes and on the circuit surfaces to enhance conductivity and solderability.

-Post-processing: Includes steps such as cleaning, inspection, and cutting to produce the final PCB product.

2.PCBA Manufacturing Process -Preparation: Prepare the required PCBs and electronic components.

-Soldering: Solder electronic components onto the PCB using SMT or THT technology.

-Inspection: Perform functional testing and quality inspection on the PCBA using automated testing equipment.

-Packaging: Package qualified PCBA for transportation and storage.

III. Features and Applications 1. PCB Features -Customisation: PCBs can be custom-designed according to specific requirements to meet the layout needs of different circuits and components.

-Standardisation: PCB manufacturing follows certain standards and specifications to ensure product quality and reliability.

-Flexibility: PCBs can adapt to various complex circuit designs and component layout requirements.

-Wide Application: PCBs are widely used in various electronic products, such as mobile phones, computers, and home appliances.

2. PCBA Features -Functionality: PCBA has specific functions and can be directly used for the assembly and testing of electronic products.

-Completeness: PCBA includes all necessary electronic components and PCBs, forming a complete circuit board assembly.

-Reliability: After rigorous testing and inspection, PCBA has high reliability and stability.

-Specific Application: PCBA is typically used on electronic product production lines, directly participating in the assembly and testing processes.

PCB and PCBA have significant differences in definition, function, manufacturing process, and application.

PCB serves as the carrier and foundational framework for electronic components, while PCBA is a circuit board assembly with specific functions, directly determining the performance and functionality of electronic products.

In the electronics manufacturing industry, both PCB and PCBA play indispensable roles.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.