Affiliate Blog Copy – Sell Without Selling. Earn More Now!

Affiliate Blog Copy – Sell Without Selling. Earn More Now!

PP Compound Market Outlook 2025: Supply Outlook and Key Players

Written by Lewis Fernandas » Updated on: June 17th, 2025

Introduction

The PP compound market outlook refers to the current trends, demand-supply dynamics, and key factors influencing the global market for polypropylene (PP) compounds. Polypropylene compounds are created by blending polypropylene resin with various additives, reinforcements, and modifiers to enhance specific properties, making them suitable for various applications across multiple industries. These compounds are commonly used in automotive, packaging, electronics, construction, and consumer goods, among others. The market for PP compounds is expected to experience continued growth, driven by technological advancements, increasing demand from end-user industries, and a shift towards lightweight materials in sectors like automotive and packaging.

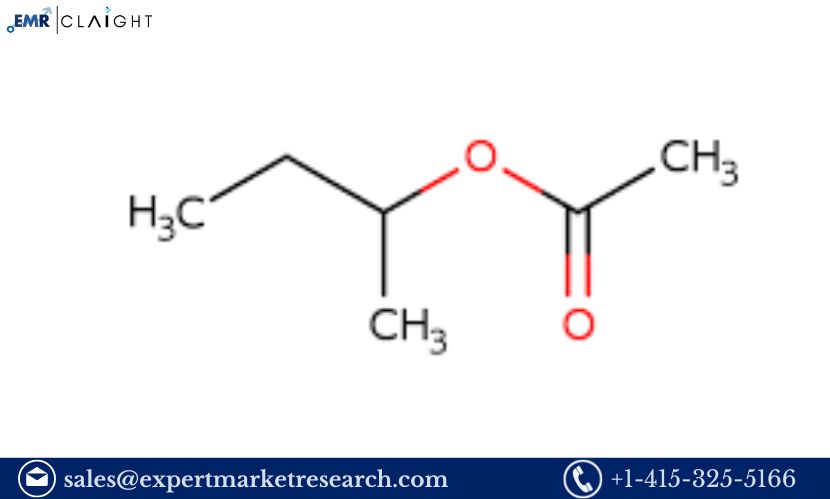

What are PP Compounds?

PP compounds are engineered materials made by modifying pure polypropylene resin to achieve desired properties, such as improved strength, heat resistance, flexibility, or electrical conductivity. The process typically involves the addition of fillers, plasticizers, stabilizers, colorants, or reinforcements like glass fibers to the polypropylene base resin.

Key characteristics of PP compounds include:

Lightweight and Durable: PP compounds are known for their low density and long-lasting durability, making them ideal for use in automotive and packaging applications.

Chemical Resistance: These compounds offer excellent resistance to chemicals, which makes them suitable for a wide range of industrial applications.

Versatility: PP compounds can be modified for various applications, offering flexibility in terms of physical properties, including hardness, toughness, and impact resistance.

Market Overview

The PP compound market is a sub-segment of the larger polypropylene market, and its demand is driven by the increasing need for high-performance, lightweight, and cost-effective materials across various industries. The automotive, packaging, and construction sectors are the primary consumers of PP compounds, and the market is expanding due to the growing trend of using advanced materials that can provide greater functionality at lower costs.

Key Applications of PP Compounds

Automotive Industry: PP compounds are widely used in the automotive sector due to their lightweight nature, which helps in improving fuel efficiency and reducing overall vehicle weight. They are used in interior parts, exterior parts, bumpers, and under-the-hood applications.

Packaging: The use of PP compounds in packaging materials has seen significant growth, particularly in food packaging, due to their resistance to moisture, chemicals, and high temperatures. PP compounds are used in bottles, containers, and films.

Consumer Goods: Many household items, including containers, appliances, and furniture, are made using PP compounds. Their versatility in design and ease of molding make them ideal for the consumer goods industry.

Electronics: PP compounds are used in the electronics industry for manufacturing components like connectors, insulators, and enclosures. Their electrical insulation properties and durability are key benefits in these applications.

Construction: In the construction sector, PP compounds are used in plumbing, electrical cables, and insulation, thanks to their durability and resistance to harsh environmental conditions.

Market Drivers

The global PP compound market is influenced by a number of factors that are driving growth and shaping the outlook of the industry:

1. Increasing Demand for Lightweight Materials in Automotive

One of the major drivers of the PP compound market is the increasing demand for lightweight materials in the automotive industry. The need for fuel-efficient vehicles and the push towards electric vehicles (EVs) have led to a growing adoption of PP compounds. These materials help reduce vehicle weight, improving fuel economy and lowering carbon emissions. PP compounds also offer cost advantages in automotive manufacturing, as they are cheaper than many traditional materials like metals.

2. Shift to Sustainable and Eco-friendly Materials

Sustainability and eco-friendliness are significant trends shaping the PP compound market. With growing environmental concerns and stricter regulations regarding plastic waste, there is a shift towards the use of recyclable materials in many industries. PP is inherently recyclable, making PP compounds an attractive choice for manufacturers aiming to reduce their environmental footprint.

3. Advancements in Packaging Solutions

The packaging industry is another key driver of the PP compound market. The increasing demand for sustainable, durable, and lightweight packaging solutions has spurred the growth of PP compounds. In food packaging, PP compounds offer excellent barrier properties, are resistant to high temperatures, and can be easily molded into a wide variety of forms, including rigid containers and flexible films.

4. Technological Innovations in PP Compound Production

Advances in production technologies have made PP compounds more versatile and cost-effective. Innovations such as new blending techniques, better additives, and reinforcements have expanded the range of applications for PP compounds. These innovations allow for the creation of PP compounds with improved properties, such as enhanced strength, heat resistance, and impact resistance.

5. Growth of End-User Industries in Emerging Economies

The expansion of key end-user industries, particularly in emerging economies in Asia-Pacific, Latin America, and the Middle East, is contributing significantly to the growth of the PP compound market. Rising industrialization, urbanization, and consumer demand in these regions are driving the demand for high-performance materials like PP compounds. Automotive manufacturing, construction, and packaging sectors in these regions are witnessing rapid growth, which is further fueling market expansion.

Global Supply and Demand Outlook

The global supply and demand dynamics for PP compounds are shaped by various factors, including regional production capabilities, raw material availability, and global consumption patterns.

1. Regional Supply Dynamics

Asia-Pacific: The Asia-Pacific region is the largest producer and consumer of PP compounds, driven by the strong automotive, packaging, and consumer goods industries in countries like China, India, Japan, and South Korea. China is one of the largest markets for PP compounds, both in terms of production and consumption.

North America: North America, particularly the United States, is another significant market for PP compounds, with strong demand from the automotive, packaging, and construction sectors. The region benefits from a well-established manufacturing base and technological advancements in production processes.

Europe: Europe is witnessing steady growth in the demand for PP compounds, driven by demand from the automotive and packaging industries. European manufacturers are focusing on sustainable production methods, and the region is seeing increasing adoption of eco-friendly PP compounds.

Middle East and Africa: In the Middle East and Africa, the growing automotive industry and expanding infrastructure are driving the demand for PP compounds. The presence of large petrochemical production hubs in the region supports the availability of PP resins and compounds.

2. Demand-Supply Imbalances

While demand for PP compounds is generally growing, supply imbalances can occur due to factors such as raw material shortages, production capacity constraints, and fluctuations in energy prices. Raw materials like polypropylene resin are sourced from petroleum, and any disruptions in oil and gas production can affect the availability and cost of PP compounds. Additionally, geopolitical factors and trade barriers can impact the global supply chain.

Key Market Players

Several key players dominate the global PP compound market, offering a wide range of products and solutions across various end-use industries. These players are focused on expanding their production capacities, introducing innovative products, and forming strategic partnerships to maintain a competitive edge.

1. LyondellBasell Industries

LyondellBasell is one of the leading players in the global PP compound market, with a strong portfolio of products used across automotive, packaging, and industrial applications. The company is known for its high-performance PP compounds and focuses heavily on innovation and sustainability.

2. SABIC

SABIC, a global leader in chemicals, offers a broad range of PP compounds used in industries such as automotive, packaging, and construction. The company is focused on enhancing product performance and sustainability through technological advancements and strategic collaborations.

3. ExxonMobil Chemical

ExxonMobil Chemical is another prominent player in the PP compound market, offering advanced solutions for automotive, packaging, and consumer goods applications. The company’s expertise in polymer technology and innovation has helped it maintain a strong presence in the market.

4. Dow Chemical Company

Dow Chemical is a major manufacturer of PP compounds, with a focus on delivering high-quality materials that meet the specific needs of automotive, packaging, and electronics industries. The company’s commitment to sustainability and product innovation has helped it remain a leader in the market.

5. Braskem

Braskem is a significant producer of PP compounds, particularly in Latin America, with a wide range of applications in packaging, automotive, and industrial sectors. The company is known for its focus on sustainability and its efforts to develop eco-friendly PP solutions.

FAQ

1. What are PP compounds used for?

PP compounds are used in automotive parts, packaging materials, consumer goods, electronics, and construction applications due to their customizable properties.

2. How are PP compounds made?

PP compounds are made by blending polypropylene resin with various additives, reinforcements, and modifiers to enhance specific properties like strength, heat resistance, or flexibility.

3. Who are the key players in the PP compound market?

Key players in the PP compound market include LyondellBasell, SABIC, ExxonMobil Chemical, Dow Chemical, and Braskem.

4. Which industries drive the demand for PP compounds?

The automotive, packaging, consumer goods, electronics, and construction industries are the primary drivers of demand for PP compounds.

5. What are the key growth drivers in the PP compound market?

Key growth drivers include increasing demand for lightweight materials in automotive, technological innovations, the shift to sustainable materials, and rising industrialization in emerging economies.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.