The Impact of Fabric Choice on Embroidery Digitizing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Embroidery digitizing is a meticulous process where designs are converted into digital files for embroidery machines. One of the critical factors that significantly influence the success of embroidery digitizing is the choice of fabric. Different fabrics behave differently under the needle, and understanding these nuances is crucial for achieving high-quality embroidery. In this article, we’ll explore the impact of fabric choice on embroidery digitizing, discuss common challenges, and provide tips to ensure optimal results. The importance of professional embroidery digitizing services will also be highlighted to emphasize achieving flawless embroidery.

Understanding Fabric Characteristics

Why Fabric Choice Matters

The fabric's texture, weight, stretchability, and weave all play a crucial role in how the embroidery will look and last. Choosing the right fabric ensures that the design is crisp, the stitches hold well, and there is minimal distortion.

Types of Fabrics

Woven Fabrics: These include cotton, linen, and denim. They are stable and hold embroidery well, making them ideal for detailed designs.

Knit Fabrics: Such as jersey and interlock, which are stretchable and require special attention to prevent distortion.

Specialty Fabrics: Velvet, silk, and leather require careful handling and specific digitizing techniques to ensure quality embroidery.

Impact on Embroidery Digitizing

Stabilization Requirements

Different fabrics require different stabilizers to prevent puckering and stretching. For instance, lightweight fabrics might need a cut-away stabilizer, while heavier fabrics might only need a tear-away stabilizer.

Stitch Density and Type

The stitch density must be adjusted according to the fabric. High-density stitches on lightweight fabrics can cause puckering, while low-density stitches on heavy fabrics might not cover adequately.

Push and Pull Compensation

Fabrics tend to move while being embroidered. Understanding the push and pull compensation is essential to ensure that the design does not distort. This adjustment is crucial for stretchy fabrics like knits.

Common Challenges with Different Fabrics

Lightweight Fabrics

Lightweight fabrics like chiffon and organza are prone to puckering. Using the correct stabilizer and reducing stitch density can help mitigate this issue.

Stretchy Fabrics

Fabrics like spandex and knits stretch, causing distortion. Using a ballpoint needle, reducing stitch density, and applying appropriate stabilizers are essential steps to handle these fabrics.

Heavyweight Fabrics

Denim and canvas are heavy and sturdy. They require needles that can penetrate without breaking and designs that are not too dense, to avoid thread breakage and machine strain.

Specialty Fabrics

Silk, velvet, and leather need careful digitizing to prevent damage. Lower stitch densities, specialized needles, and correct stabilization are critical for these materials.

Tips for Successful Embroidery Digitizing

Conducting Fabric Tests

Always run a test embroidery on a scrap piece of the fabric to check how it responds to the needle, thread, and design. Adjustments can be made based on this test.

Choosing the Right Stabilizer

The choice of stabilizer is crucial. For instance, water-soluble stabilizers work well for lightweight fabrics, while cut-away stabilizers are better for knits and stretchy fabrics.

Adjusting Stitch Density

Reduce stitch density for lightweight and stretchy fabrics to avoid puckering. For heavier fabrics, ensure that the density is adequate to cover the design area without causing thread breaks.

Using Appropriate Needles

Select the right needle type and size for the fabric. Ballpoint needles are suitable for knits, while sharp needles work well with woven fabrics.

Applying Proper Tension

Adjust the machine tension according to the fabric and thread type. Incorrect tension can lead to thread breaks, skipped stitches, or puckering.

Importance of Professional Embroidery Digitizing Services

Expertise and Precision

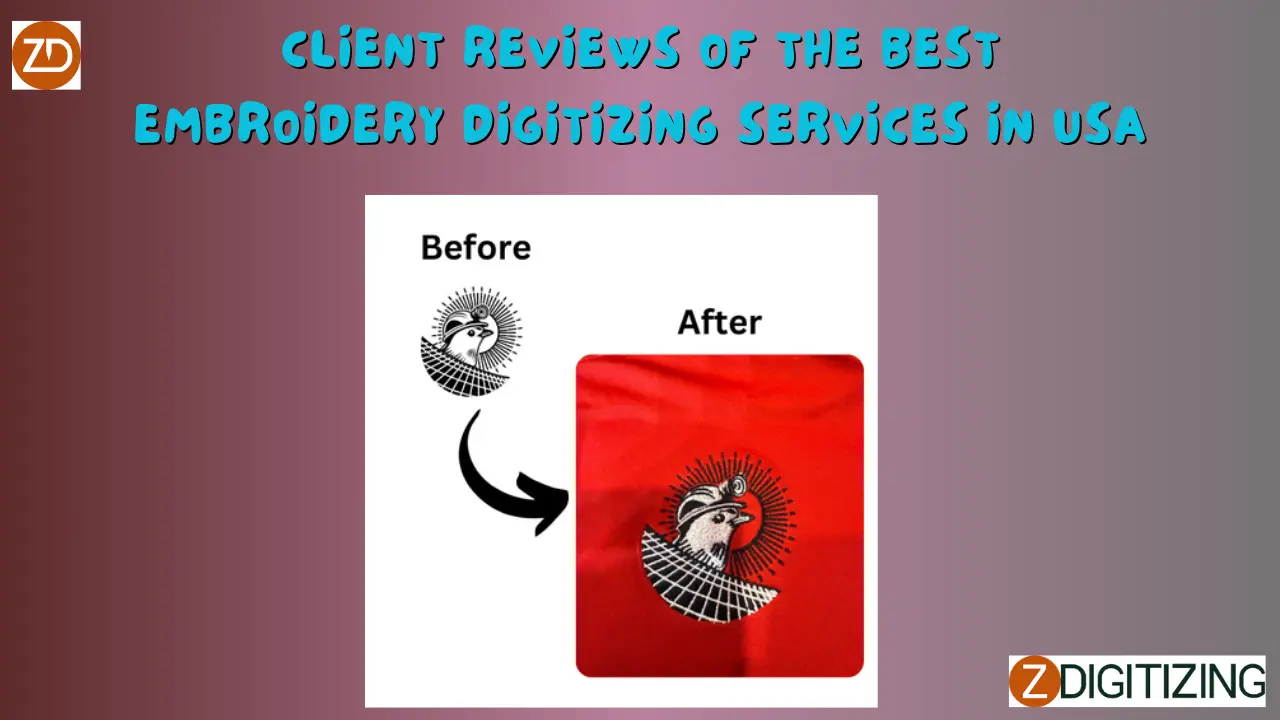

Professional digitizing embroidery service bring expertise and precision to the table. They understand the nuances of different fabrics and can adjust the digitizing process accordingly.

Advanced Software and Tools

Professionals use advanced software and tools to create digitized designs that are optimized for the fabric, ensuring high-quality embroidery.

Quality Assurance

Professional services include quality checks to ensure that the digitized design translates well onto the fabric, reducing the risk of errors and rework.

Conclusion

The choice of fabric has a profound impact on the embroidery digitizing process. Understanding fabric characteristics, adjusting stabilization, stitch density, and compensation accordingly can significantly enhance the quality of the embroidery. Leveraging professional digitizing services for embroidery can further ensure that your designs are digitized accurately and efficiently, resulting in beautiful and durable embroidered products. Remember, testing and adjusting your approach based on the fabric is key to achieving the best results in embroidery digitizing.

FAQs

1. Why is fabric choice important in embroidery digitizing?

Fabric choice affects how the embroidery will look and last. Different fabrics have unique characteristics that influence stabilization, stitch density, and compensation adjustments.

2. How can I prevent puckering on lightweight fabrics?

To prevent puckering, use a cut-away stabilizer, reduce stitch density, and run a test embroidery to make necessary adjustments.

3. What are the best practices for embroidering on stretchy fabrics?

For stretchy fabrics, use a ballpoint needle, apply an appropriate stabilizer, reduce stitch density, and adjust the machine tension.

4. How do professional embroidery digitizing services ensure quality?

Professional services use advanced software, conduct fabric tests, and perform quality checks to ensure the digitized design is optimized for the fabric and results in high-quality embroidery.

5. What types of stabilizers should I use for different fabrics?

Lightweight fabrics: Water-soluble or cut-away stabilizers.

Stretchy fabrics: Cut-away stabilizers.

Heavyweight fabrics: Tear-away stabilizers.

Specialty fabrics: Customized stabilizers based on fabric sensitivity.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.