Alloy Steel SA 213 T11 Tubes: Properties, Applications, and Benefits

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

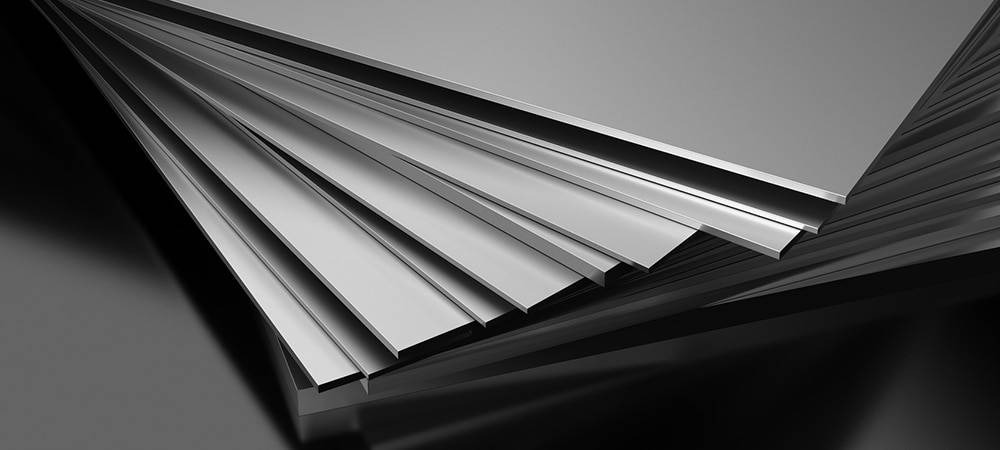

Alloy Steel SA 213 T11 Tubes are high-performance ferritic alloy tubes designed primarily for high-temperature and high-pressure applications in various industries. Recognized for their excellent mechanical strength, corrosion resistance, and thermal stability, these tubes are extensively used in boilers, heat exchangers, superheaters, and other critical equipment.

This article delves into the core features, chemical composition, mechanical properties, manufacturing standards, and industrial applications of SA 213 T11 Tubes.

Overview of SA 213 T11 Alloy Steel

The SA 213 T11 tube falls under the ASTM A213 specification, which covers seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. The T11 grade, specifically, is a low-alloy steel that contains Chromium (1–1.5%) and Molybdenum (0.44–0.65%), contributing to its enhanced resistance against oxidation, corrosion, and high-temperature stress.

These tubes are available in various forms including seamless, cold-drawn, and hot-rolled finishes and are widely recognized for their consistent quality, dimensional accuracy, and adaptability in extreme working conditions.

Chemical Composition of SA 213 T11 Tubes

The properties of T11 tubes are largely defined by their chemical makeup:

Element Composition (%)

Carbon (C) 0.05 – 0.15

Manganese (Mn) 0.30 – 0.60

Phosphorus (P) ≤ 0.025

Sulfur (S) ≤ 0.025

Silicon (Si) 0.50 – 1.00

Chromium (Cr) 1.00 – 1.50

Molybdenum (Mo) 0.44 – 0.65

This optimized combination offers a balance of strength, hardness, ductility, and resistance to thermal degradation.

Mechanical Properties of SA 213 T11 Tubes

The mechanical properties of the alloy make it suitable for high-pressure services. Below are the typical mechanical properties:

Property Value

Tensile Strength ≥ 415 MPa

Yield Strength ≥ 205 MPa

Elongation ≥ 30%

Hardness ≤ 85 HRB

These properties ensure structural integrity under thermal cycling and mechanical loading.

Manufacturing Process

The production of SA 213 T11 tubes follows stringent ASTM guidelines to ensure performance in high-stress environments.

1. Material Selection

High-grade alloy steel billets are selected based on ASTM A213 specifications.

2. Seamless Tube Formation

Using extrusion or rotary piercing, the billets are converted into seamless tubes, ensuring no weld seam weaknesses.

3. Cold Drawing (if applicable)

For precise dimensions and smoother surfaces, the tubes may undergo cold drawing.

4. Heat Treatment

SA 213 T11 tubes are normalized or tempered to achieve desired mechanical properties. Common treatments include:

Normalization

Tempering

Annealing

5. Testing and Inspection

Tubes undergo rigorous testing, including:

Hydrostatic testing

Ultrasonic inspection

Eddy current testing

Hardness testing

Flattening and flaring tests

Key Features of SA 213 T11 Tubes

Excellent Thermal Resistance:

Suitable for use in temperatures up to 600°C without significant deformation or oxidation.

High Mechanical Strength:

Withstands high pressures and mechanical stresses, making it ideal for power generation and petrochemical plants.

Corrosion and Oxidation Resistance:

The presence of chromium and molybdenum imparts significant resistance to corrosion, scaling, and oxidation.

Dimensional Precision:

Cold-drawn and seamless varieties ensure tight tolerances and smooth internal surfaces, crucial for fluid dynamics.

Longevity and Reliability:

Low wear and high durability minimize maintenance and replacement costs.

Applications of SA 213 T11 Tubes

Due to their superior performance characteristics, these tubes find application across a wide range of industries:

1. Power Generation

Used in:

Superheaters

Boilers

Heat exchangers

T11 tubes handle superheated steam efficiently, maintaining performance under cyclical temperature variations.

2. Oil & Gas Industry

In refineries and petrochemical plants, these tubes transport hot fluids, support desulfurization units, and are used in high-pressure service lines.

3. Chemical Processing

The tubes resist acidic environments and high-pressure chemical reactions, making them ideal for reactors and exchangers.

4. Marine Engineering

In marine boilers and heat exchangers, the corrosion resistance of T11 tubes is a significant advantage.

5. Aerospace and Defense

Used where both strength and heat resistance are crucial, especially in engine components and high-performance heat management systems.

Benefits of Using SA 213 T11 Tubes

Cost-Efficiency:

Compared to stainless steels, T11 offers good performance at a lower cost, especially in high-temperature environments.

Versatility:

Compatible with various joining techniques such as welding, flanging, and threading.

Eco-Friendly Choice:

Alloy steel tubes can be recycled, and their long service life reduces waste and downtime.

Availability in Multiple Forms:

Can be supplied in straight lengths, U-bent tubes, coils, and custom-cut sizes.

Standards and Certifications

SA 213 T11 tubes conform to several international standards:

ASTM A213 / ASME SA213

ISO 9329

EN 10216-2

DIN 17175

Manufacturers and suppliers usually provide:

Mill Test Certificates (MTC)

Third-party inspection reports

Non-destructive testing results

Conclusion

Alloy Steel SA 213 T11 Tubes are a trusted solution for high-temperature and high-pressure applications across major industries. Their reliable performance, cost-effectiveness, and compliance with global standards make them indispensable in demanding environments. Whether it’s a power plant’s boiler system or a refinery’s heat exchanger, T11 tubes deliver the robustness and stability needed for optimal performance.

When sourcing SA 213 T11 tubes, it’s essential to choose certified manufacturers and suppliers who follow stringent quality assurance practices, ensuring durability, safety, and compliance with technical specifications.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.