ASTM A335 P22 Pipes: High-Performance Alloy Steel Pipes for Elevated Temperature Applications

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

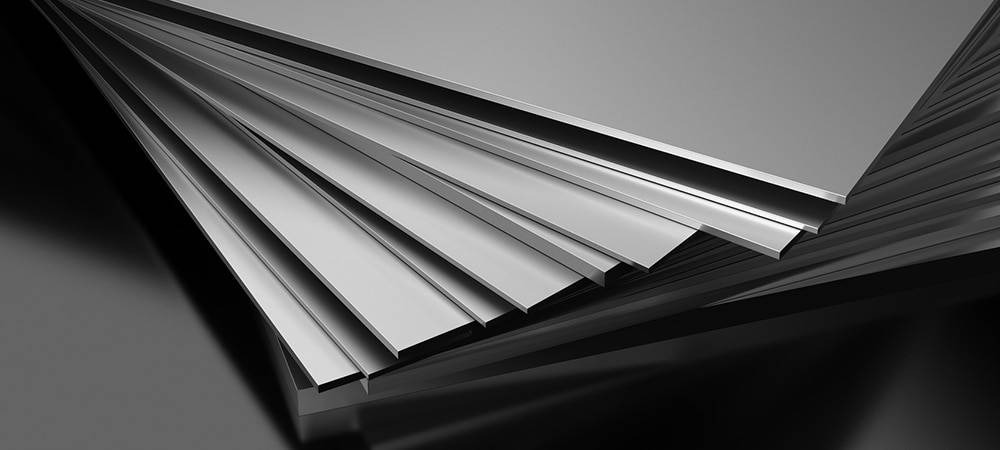

ASTM A335 P22 pipes are seamless ferritic alloy steel pipes engineered for use in high-temperature services and pressure systems. These pipes are part of the ASTM A335 specification, which is widely recognized in industries like power generation, oil and gas, refineries, and petrochemicals for its exceptional strength, thermal resistance, and corrosion resistance. The P22 grade is particularly valued for its performance in applications involving steam, heat, and aggressive working environments.

Chemical Composition of ASTM A335 P22 Pipes

Element Composition (%)

Carbon (C) 0.05 – 0.15

Manganese (Mn) 0.30 – 0.60

Phosphorus (P) ≤ 0.025

Sulfur (S) ≤ 0.025

Silicon (Si) 0.50 – 1.00

Chromium (Cr) 1.90 – 2.60

Molybdenum (Mo) 0.87 – 1.13

The elevated chromium and molybdenum content provide excellent strength, oxidation resistance, and enhanced creep strength at elevated temperatures.

Mechanical Properties of ASTM A335 P22 Pipes

Property Value

Tensile Strength ≥ 415 MPa

Yield Strength ≥ 205 MPa

Elongation ≥ 30%

Hardness (HBW) ≤ 163

These mechanical properties ensure durability and reliability in extreme operating conditions, such as those found in power boilers and high-pressure steam lines.

Key Features of ASTM A335 P22 Pipes

1. High Thermal Resistance

P22 pipes can withstand extremely high temperatures, making them ideal for use in steam pipelines and superheaters.

2. Excellent Corrosion Resistance

Thanks to its alloy composition, ASTM A335 P22 resists oxidation, sulfide corrosion, and high-temperature scaling.

3. Seamless Design

The seamless construction ensures uniform strength and pressure resistance, minimizing the risk of leaks or ruptures.

4. Weldability and Fabrication

P22 pipes offer good weldability, allowing for ease of fabrication in field installations and custom setups.

5. Long Service Life

Superior strength and resistance to environmental degradation result in minimal maintenance and long operational life.

Applications of ASTM A335 P22 Pipes

• Thermal and Nuclear Power Plants: For steam pipelines, reheaters, and headers.

• Oil & Gas Refineries: Ideal for hot fluid and gas transport systems.

• Petrochemical and Chemical Plants: Withstands aggressive media under heat and pressure.

• Boiler and Heat Exchanger Systems: Used in boilers, superheaters, and economizers.

• Fossil Fuel Plants: Especially where high creep strength and oxidation resistance are essential.

Product Range and Availability

ASTM A335 P22 pipes are available in a broad range of sizes and specifications:

• Size Range: 1/2” NB to 36” NB

• Wall Thickness: SCH 40 to SCH XXS and custom as needed

• Lengths: Single random, double random, and cut lengths

• Ends: Plain end, beveled end, threaded

• Forms: Hot-finished, cold-drawn

Pipes are delivered in normalized and tempered, quenched and tempered, or annealed conditions depending on customer requirements.

Standards and Certifications

• ASTM A335 / ASME SA335

• IBR (Indian Boiler Regulation) Approved

• NACE MR0175 (on request)

• Third-party inspection from agencies like TUV, BV, SGS, or Lloyd’s as required

All pipes come with full traceability and manufacturer test certificates.

Conclusion

ASTM A335 P22 pipes are an essential choice for industries operating in high-pressure and high-temperature environments. Their combination of high tensile strength, thermal stability, corrosion resistance, and ease of fabrication makes them indispensable in power generation, oil and gas, and process industries. Choosing ASTM A335 P22 ensures safety, performance, and durability for critical piping applications.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.