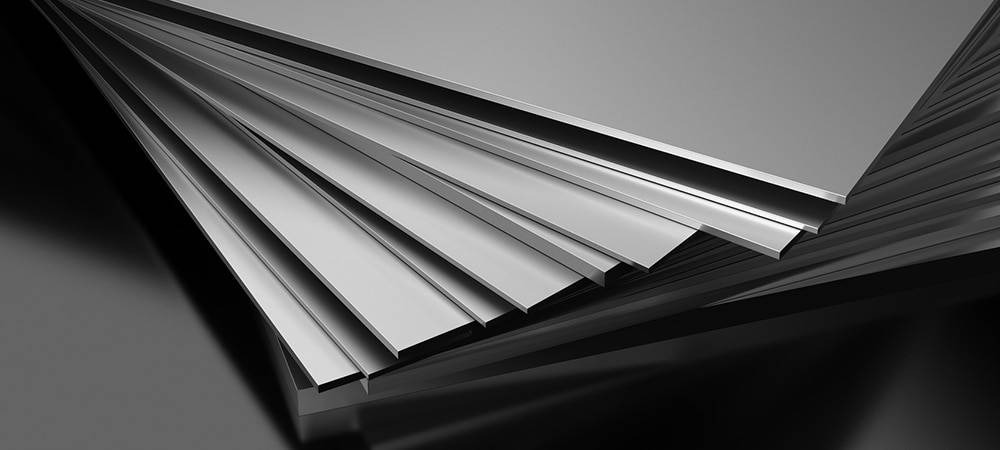

Stainless Steel 317 Sheets: Properties, Applications, and Advantages

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless steel is one of the most widely used materials across numerous industries due to its excellent mechanical properties, corrosion resistance, and durability. Among the various grades, Stainless Steel 317 Sheets stand out for their superior resistance to chemical attack and high-temperature performance. These sheets are specifically designed to perform well in severe environments, including those involving corrosive chemicals and high stress.

In this article, we will explore the key features, chemical composition, mechanical properties, manufacturing standards, applications, and advantages of Stainless Steel 317 sheets.

Overview of Stainless Steel 317

Stainless Steel 317 is a molten steel alloy with higher molybdenum content than its 316-grade counterpart. It is an austenitic chromium-nickel stainless steel that includes significant additions of molybdenum to enhance its corrosion resistance, especially in acidic and chloride-containing environments. The increased molybdenum and nickel content gives it better creep, stress-to-rupture, and tensile strength at elevated temperatures.

317 stainless steel is non-magnetic in the annealed condition and remains non-magnetic even after cold working, which is advantageous in certain sensitive applications.

Chemical Composition of Stainless Steel 317 Sheets

Element Content (%)

Chromium (Cr) 18.0 – 20.0

Nickel (Ni) 11.0 – 15.0

Molybdenum (Mo) 3.0 – 4.0

Manganese (Mn) ≤ 2.0

Silicon (Si) ≤ 1.0

Carbon (C) ≤ 0.08

Phosphorus (P) ≤ 0.045

Sulfur (S) ≤ 0.03

Iron (Fe) Balance

The presence of higher molybdenum and nickel contents enhances the material’s resistance to pitting and crevice corrosion in chloride-rich environments, making it more durable than standard stainless steel grades.

Mechanical Properties

Property Value

Density 8.0 g/cm³

Tensile Strength 75,000 psi (515 MPa)

Yield Strength 30,000 psi (205 MPa)

Elongation at Break 35%

Modulus of Elasticity 193 GPa

Hardness (Brinell) ≤ 217 HB

These mechanical properties make SS 317 sheets suitable for high-stress applications, especially where strength and corrosion resistance are essential.

Key Features and Benefits

1. Superior Corrosion Resistance

The increased molybdenum content in SS 317 significantly improves its resistance to chemical environments, particularly sulfurous, acetic, formic, citric, and tartaric acids. This makes the alloy especially suitable for chemical processing industries.

2. Excellent High-Temperature Strength

317 stainless steel offers excellent performance at elevated temperatures. It maintains its strength and form even at temperatures exceeding 870°C, making it ideal for high-temperature service.

3. Resistance to Pitting and Crevice Corrosion

SS 317 sheets are highly resistant to localized corrosion, including pitting and crevice corrosion, particularly in chloride-rich environments such as marine or coastal applications.

4. Good Fabrication and Welding Characteristics

SS 317 can be easily fabricated using standard techniques. It exhibits good weldability and can be welded using common methods such as TIG, MIG, and resistance welding, with or without filler metals.

5. Non-Magnetic Nature

Being non-magnetic in the annealed condition, SS 317 is suitable for applications that require non-magnetic properties, such as in electronic and instrumentation industries.

Applications of Stainless Steel 317 Sheets

Stainless Steel 317 sheets are utilized across a wide range of demanding industries due to their exceptional properties:

● Chemical Processing Equipment

Due to their excellent corrosion resistance to a broad range of chemicals, SS 317 sheets are used in the fabrication of equipment such as tanks, reactors, evaporators, and heat exchangers.

● Petrochemical Industry

Used in refining units, oil and gas processing equipment, and piping systems due to their resistance to acidic and high-temperature environments.

● Pharmaceutical Industry

Stainless Steel 317 is used in cleanroom environments and for making equipment such as dryers, fermenters, and processing tanks due to its non-reactive nature.

● Food and Beverage Industry

Highly resistant to food acids and corrosion, SS 317 sheets are used in dairy, brewery, and food processing applications.

● Marine Applications

Thanks to its resistance to saltwater corrosion, it is used in marine hardware, shipbuilding, and offshore platforms.

● Pulp and Paper Industry

SS 317 is used in digester systems, bleaching equipment, and other components that handle aggressive chemicals like sodium hypochlorite and chlorine dioxide.

Forming and Machining

While SS 317 is tougher than 304 or 316 due to higher alloying elements, it can still be machined using standard methods. Machining is best done at slower speeds with adequate lubrication and rigid tooling to prevent work hardening.

Forming SS 317 requires higher forces compared to lower alloy grades, but it is still feasible using conventional forming processes. Annealing after cold working is recommended to restore its ductility and corrosion resistance.

Welding and Heat Treatment

SS 317 can be welded using most standard methods:

TIG (GTAW)

MIG (GMAW)

Shielded Metal Arc Welding (SMAW)

Use of AWS E317 electrodes or ER317 filler metals is recommended. Preheating is generally not required, and post-weld heat treatment may be performed to relieve stresses.

For heat treatment, solution annealing is performed at temperatures ranging from 1010°C to 1120°C followed by rapid cooling, usually in water or air. This treatment restores corrosion resistance lost during welding or forming.

Finishes and Sizes

Stainless Steel 317 sheets are available in various finishes such as:

2B (Cold Rolled)

BA (Bright Annealed)

No. 4 (Brushed Finish)

No. 8 (Mirror Finish)

Standard thickness ranges from 0.3mm to 50mm, and sheet dimensions can vary according to application requirements, often offered in cut-to-size or custom dimensions.

Comparison with Other Stainless Steels

Property / Grade SS 304 SS 316 SS 317

Molybdenum No 2-3% 3-4%

Corrosion Resistance Good Better Excellent

High-Temp Strength Moderate High Higher

Cost Low Moderate Higher

SS 317 sheets are a premium-grade material compared to SS 304 and SS 316, offering better corrosion resistance and strength, especially under aggressive chemical and high-temperature conditions.

Conclusion

Stainless Steel 317 Sheets provide a unique combination of high strength, excellent corrosion resistance, and durability. These qualities make them ideal for challenging environments such as chemical processing, marine, and high-temperature industrial settings. While they are more expensive than lower-grade stainless steels, their long service life and low maintenance requirements often result in lower life-cycle costs.

Whether you're manufacturing industrial processing equipment or operating in coastal or chemical-laden environments, SS 317 sheets are a smart investment for reliable, long-term performance.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.