Stainless Steel 309 Round Bars: Properties, Applications & Benefits

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

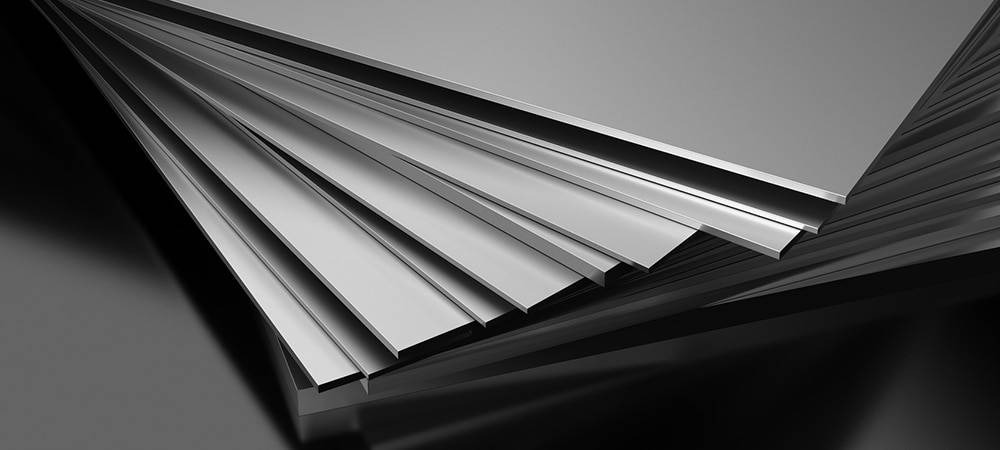

Stainless Steel 309 Round Bars are high-alloy austenitic stainless steel products known for their excellent resistance to oxidation and high-temperature corrosion. These bars are widely utilized in a range of industries due to their exceptional mechanical properties and chemical composition. Designed to perform in extreme environments, Stainless Steel 309 Round Bars have become a go-to material for high-temperature service applications.

Overview of Stainless Steel 309

Stainless Steel 309 is an austenitic chromium-nickel stainless steel that offers outstanding heat resistance and oxidation resistance. It contains higher levels of chromium (22-24%) and nickel (12-15%) compared to standard 304 stainless steel. This increased alloy content allows 309 to withstand high temperatures—up to 980°C (1800°F) in continuous service and up to 1035°C (1900°F) in intermittent service.

Its low carbon content ensures minimal carbide precipitation during welding, improving weldability and making it suitable for a variety of fabrication processes.

Key Properties of SS 309 Round Bars

High Temperature Resistance:

One of the most significant advantages of 309 round bars is their ability to withstand high temperatures. They perform well under thermal cycling and resist scaling at elevated temperatures.

Corrosion Resistance:

These bars offer excellent resistance to oxidation, sulfidation, and carburization. This makes them ideal for environments involving acids, chemicals, and other corrosive agents.

Mechanical Strength:

SS 309 round bars possess good tensile strength and yield strength, ensuring reliability and durability in demanding mechanical applications.

Weldability and Fabrication:

The material is easy to weld using standard methods like TIG, MIG, and arc welding. It also exhibits good machinability, formability, and toughness.

Creep Resistance:

309 stainless steel provides good creep resistance, which is critical for long-term applications at elevated temperatures.

Chemical Composition

Element Content (%)

Chromium (Cr) 22.0 – 24.0

Nickel (Ni) 12.0 – 15.0

Carbon (C) ≤ 0.20

Manganese (Mn) ≤ 2.00

Silicon (Si) ≤ 1.00

Phosphorus (P) ≤ 0.045

Sulfur (S) ≤ 0.030

Iron (Fe) Balance

Mechanical Properties

Property Value

Tensile Strength ≥ 550 MPa

Yield Strength (0.2% proof) ≥ 205 MPa

Elongation (% in 50mm) ≥ 40%

Hardness (Brinell) ≤ 220 HB

Applications of Stainless Steel 309 Round Bars

Due to their excellent thermal and corrosion resistance, Stainless Steel 309 round bars are used across diverse industries:

Heat Treatment Equipment: Used in furnace parts, heat exchangers, and burner components.

Chemical Processing: Ideal for equipment exposed to strong oxidizing agents.

Petrochemical Industry: Used in reactors, pipelines, and distillation columns.

Power Generation: Utilized in boilers and high-temperature turbine components.

Cement and Steel Plants: Used in kilns, conveyors, and exhaust systems.

Aerospace & Marine: Suitable for exhaust systems, engine parts, and other high-heat applications.

Food Processing: Preferred in environments that require clean, corrosion-resistant materials.

Advantages of Using SS 309 Round Bars

Superior Oxidation Resistance

Especially suitable for service in atmospheres containing sulfur and other high-temperature oxidants.

Long Service Life

High resistance to thermal fatigue and mechanical stress increases durability and reduces maintenance.

Versatile Fabrication

Can be easily cut, welded, and formed into complex shapes and designs.

Hygienic and Low Maintenance

Ideal for industries where sanitation is essential, such as food and pharmaceuticals.

Cost-Effective at High Temperatures

Though it is more expensive than lower-grade stainless steel, its long-term performance in high-temperature settings reduces overall lifecycle costs.

Conclusion

Stainless Steel 309 Round Bars are a premium-grade material engineered for high-performance applications in challenging environments. With outstanding heat and corrosion resistance, good weldability, and reliable mechanical strength, SS 309 is a trusted choice for industries where performance under pressure is essential. Whether in furnaces, chemical plants, or power stations, these round bars deliver durability, safety, and efficiency.

For manufacturers, suppliers, and end-users seeking reliable materials for elevated temperature applications, Stainless Steel 309 Round Bars offer a high-value solution with unmatched performance benefits.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.