Centrifugal and Chemical Pumps for Chemical Process Industry

SMS Pumps & Engineers is a leading company focusing on the design and manufacture of centrifugal pumps, vertical centrifugal pump, chemical pumps and associated equipment, mostly for chemical, food, textile, ceramic, laminate, solvent transfers, warm exchangers, and numerous various other industrial markets. SMS Pumps & Engineers has actually just sent off multiple orders of centrifugal and chemical pumps to the reputed chemical industry.

The esteemed chemical sector with a strong reputation in the chemical market and huge knowledge of the marketplace, paired with our bespoke centrifugal and chemical pumps for bringing a winning suggestion of strong technology and manufacturing.

Our pump's flexibility to industrial demands makes it an effective tool for sectors to achieve targets. With their high efficiencies, our industrial pumps are all set to fulfill the requirements of future power performance guidelines. Amongst numerous industrial pumping remedies, one substantial benefits of using a thermic fluid pump. These pumps are engineered for high-temperature liquid flow, ensuring effective warm transfer with minimal power loss.

At SMS Pumps & Engineers, we attend to all the challenges to create a world-class series of commercial pumps that are well fit for all stress applications from low to high.

Here in this blog site, we have actually put together some of the details of why the chemical sector chose our pumps, what is centrifugal and chemical pumps, their advantages and applications, how these pumps work in the chemical market, and more.

Why Did The Reputed Chemical Market?

SMS Pumps & Engineers were largely picked because of their high effectiveness and resulting reduced power consumption.

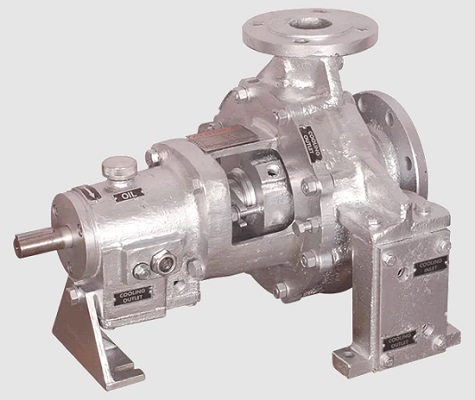

At SMS Pumps & Engineers, we make centrifugal process pump for transferring corrosive liquids, like acids, slurries, and wastewater drain, and made with rust resistance to decrease repair service and replacement costs.

By utilizing our chemical-resistant pump, sectors can lower the environmental effect of corroded cast iron pumps. Built to be durable and to resist a selection of chemicals, it ensures that no damage is created due to chemicals. When picking the appropriate pump for commercial applications, it's essential to need to know about multistage centrifugal pumps. These pumps are made to take care of high-pressure applications efficiently by utilizing several impellers to boost performance.

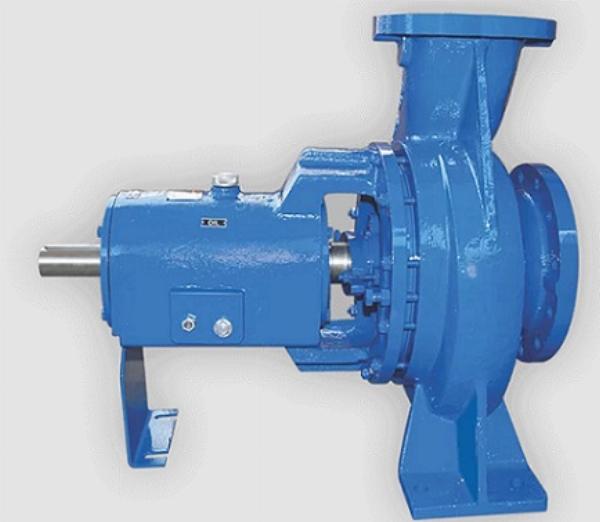

What is a Centrifugal Pump?

A centrifugal pump is a mechanical device used to move fluids by the conversion of rotational kinetic energy from one or more driven rotors, referred to as impellers.

Fluid goes into the pump impeller along its axis and is accelerated out by centrifugal pressure.

This action of the impeller results in the increase of the liquid's speed and stress that guides it towards the pump electrical outlet.

The pump case is innovatively designed to tighten the fluid from the inlet, channel it right into the impeller, and after that it decreases and manage the liquid before getting released. As a result of its high flow price capacities, abrasive solution compatibility, as well as their reasonably simple design, it is the best selection in the sectors. When choosing the ideal pump for demanding applications, it's vital to need to know about vertical multistage pumps. These pumps offer high performance and regular pressure, making them ideal for sectors needing high-pressure fluid motion.

Comprehending the vertical centrifugal pump working principle, kinds and its applications is important for selecting the best pump for industrial requirements. Upright centrifugal pumps run by utilizing an impeller to create centrifugal pressure, successfully moving fluids in applications where space is restricted or deep suction is called for.

What Is A Chemical Pump?

When the routine pumps can't assist, chemical pumps concern the rescue.

Chemical pumps are used to move chemicals and chemical slurries. They are particularly created to be corrosion and unpleasant immune to industrial liquids such as solvents, bleach, paint, etc.

These pumps are additionally utilized to transfer liquids at high pressure. It is additionally discovered handy in giving flow measurement and control for applications that need exact quantities of chemicals.

Chemical pumps become needed for sectors relocating corrosive and rough liquids of various degrees of thickness, such as sulphuric acids, acetic acid, and salt hypochlorite.

Chemical pumps are extra long lasting contrasted to conventional pumps and quickly pump hot, chilly, explosive, aggressive, harmful, unpredictable, and infected fluids. They are mainly utilized in food processing, petrochemical, and chemical industries, along with in the off-site application of high-temperature heater.

When going over industrial pumps in the sugar industry, choosing the best pump is necessary for dealing with different liquids utilized in sugar handling.

How Do Centrifugal & Chemical Pumps Work in Chemical Sector?

Due to the corrosive and rough nature of chemicals, they should be handled very carefully. For this reason, ideal pump option is important to stand up to the specific harsh chemicals.

In numerous chemical sectors, useful chemical substances such as solvents, acids, polymers, and so on, are used in the manufacturing procedure. This develops the requirement of reliable liquid management to ensure a risk-free environment and an effective manufacturing process.

Centrifugal and chemical pumps are unique and the perfect selection for chemical sectors, due to the fact that they have the capability to provide high flow prices and adjustments, which can be performed in the flow prices according to the TDH of the piping system.

These pumps are perfect for numerous industrial applications from storage and dumping to filtration and blood circulation. Both pumps collaborate with optimal efficiency to supply optimal performance and integrity with terrific stability at various operating factors.

Among the key features of a high-quality thermic fluid pump is its capability to manage extreme temperature levels while maintaining efficiency. These pumps are especially made for high-temperature warm transfer applications, guaranteeing minimal energy loss and maximum toughness.

Salient Features of Centrifugal & Chemical Pump

- Chemical Resistance

- Unpleasant Resistance

- Highly Resilient

- Energy-Saving

- Easy Flow

- Reduced Maintenance

- Size & Application Flexible

- Durable building

Applications of Centrifugal & Chemical Pump

- Cold And Hot Water Circulation

- Cooling Towers Installation

- Chemical Plants

- Slurry transfer

- Acid transfer

- Petroleum Industries

- Drug Industries

In the fast-growing chemical industries, there is a substantial demand for high-performing commercial pumps that are maintenance-free and also meet numerous industrial challenges. A thermic fluid pump plays an essential function in handling high-temperature liquids effectively while guaranteeing integrity and longevity.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.