What are the Types of Pumps?

Pump is a mechanical device made use of to transfer various fluids from one setting to one more. It is a hydraulic device that lifts a fluid from a reduced to a high level and relocate from a low-pressure area to a high-pressure area. Pumps transfer fluids by transforming the power of the fluid right into pressure energy (hydraulic energy).

Classification of Pumps

Pumps are separated into two major categories: dynamic and positive displacement

The following are a few of the pumps under these two categories:

Dynamic Pumps:

- Centrifugal pumps

- Vertical centrifugal pumps

- Horizontal centrifugal pumps

- Submersible pumps

- Fire hydrant system

Positive Displacement Pumps:

- Diaphragm pumps

- Gear pumps

- Peristaltic pumps

- Cam pumps

- Piston pumps

Dynamic Pumps

There are different sorts of dynamic pumps, several of which will certainly be talked about listed below, such as centrifugal pumps, vertical centrifugal pumps, horizontal centrifugal pumps, submersible pumps and fire hydrant systems.

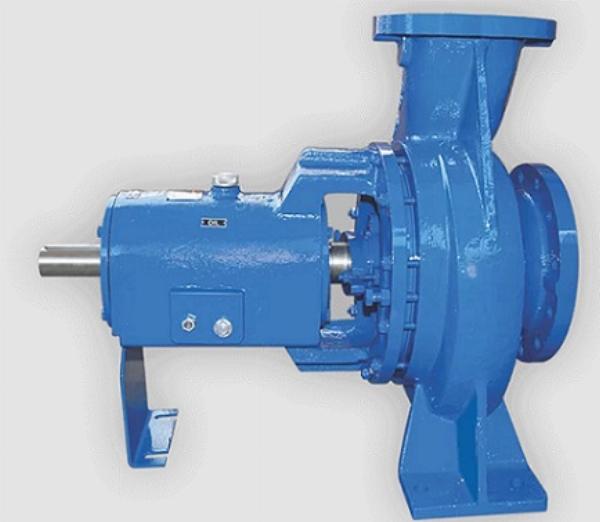

Centrifugal Pumps

These types of pumps are one of the most frequently made use of on the world. The work is extremely basic, well described and carefully examined. These pumps are robust, reliable and fairly economical to manufacture. Whenever the pump is running, the fluid stress will certainly boost from the pump's inlet to its outlet. The adjustment in pressure will drive the fluid throughout the system. A thermic fluid pumps manufacturer ensures these pumps meet the highest criteria for performance and integrity.

This pump creates an enhanced pressure by moving the mechanical power of the electric motor to the fluid throughout the rotating impeller. The fluid circulation will certainly go into the center of the impeller and drain with its vanes.

Vertical Centrifugal Pumps

Vertical centrifugal pumps are additionally referred to as cantilever pumps These pumps make use of an one-of-a-kind shaft and upkeep style that permits the quantity to fall into the pit since the bearings get on the outside of the pit. This pump version does not utilize a filled up container to cover the shaft, however uses a throttle bushing in its place. Components washing machines are a usual application for this type of pump.

Horizontal Centrifugal Pumps

These kinds of pumps consist of at the least 2 otherwise extra impellers. These pumps are utilized for pumping services. Each stage is primarily a manifold pump.

All phases are in a similar shelter and installed on a comparable shaft. A minimum of 8 added stages can be installed on separate straight shafts. Each stage improves the head by roughly equivalent quantities. A multi stage pump can additionally be a single-stage pump, otherwise a dual suction pump on the very first impeller. Different pumps have actually been provided and repaired for this type of centrifugal pump by a centrifugal multi stage pump manufacturer.

Submersible Pumps

These pumps are likewise known as stormwater, sewage and septic pumps. Applications for these pumps include mainly developing solutions, residential, commercial, business, country, local and stormwater recycling applications.

These pumps appropriate for transferring stormwater, groundwater, sewage, blackwater, greywater, rain, profession waste, chemicals, bore water and food. These plumbing applications mainly consist of various impellers such as shut type pumps, convection pumps, vortex pumps, multistage pumps, solitary channel pumps, cutting pumps or mill pumps. For different applications, a variety of alternatives are offered, consisting of high circulation, reduced circulation, low head or high head.

Fire Hydrant System

Fire hydrant pump systems are additionally known as fire hydrant booster, fire pump and fire pump. These are high pressure pumps designed to increase the fire fighting capability of a building by boosting the force within the hydrant solution, as the keys are not enough. Applications for this system consist of primarily irrigation and water circulation.

Positive Displacement Pumps

There are various kinds of volumetric pumps, some of which will be talked about listed below, such as diaphragm pumps, gear pumps, peristaltic pumps, wattle pumps, and piston pumps.

Diaphragm Pumps

Diaphragm pumps are called AOD pumps (Air Operated Diaphragm), pneumatic and AODD pumps. Applications for these pumps include mostly in continual applications such as general plant, industrial and mining. AOD pumps are specifically appropriate where power is not readily available and are or else made use of in unstable and combustible locations. These pumps are also made use of for moving chemicals, industrial wastewater, food manufacturing, below ground coal mines, etc.

These pumps are reaction pumps that consist of two diaphragms driven by condensing air. The air section of the transfer shutoff alternately applies air to both diaphragms; each diaphragm has a set of round valves or examine shutoffs.

Gear Pumps

These pumps are a rotating positive displacement pump, which implies they create a consistent quantity of liquid with each transformation. These pumps move the liquid by going into machinery inside and outside the network for a non-exciting pumping action. These pumps can pumping at high pressures and can effectively pump extremely concentrated liquids.

Gear pumps do not contain any shutoffs that cause losses such as rubbing and high impeller speeds. As a result, the pumps appropriate for handling thick liquids such as gas and oil. These pumps are not ideal for driving solids and rough liquids.

Peristaltic Pumps

Peristaltic pumps are also called tube pumps and peristaltic dosing pumps. It is a volumetric pump and the applications of these pumps are generally related to processing in the chemical, food and water therapy industries. It supplies a constant circulation for determining and mixing and is also efficient in pumping different liquids such as tooth paste and various chemicals. A centrifugal chemical pump manufacturer makes sure the finest quality and integrity for these essential applications.

Lobe Pumps

Lobe pumps are also called rotor pumps and these pumps have different qualities such as superb performance, corrosion resistance, sanitary high quality, integrity etc. These pumps can handle extremely focused liquids and solids without harming them. These pumps may work with gear pumps, besides the vanes that do not touch each other. Additionally, these pumps have premium pumping chamber compared to gear pumps that permit them to move slurry. These are made of stainless steel and are really polished.

Piston Pumps

Piston pump is a positive displacement pump, additionally called a plunger pump, in which a high pressure seal reacts through a piston. These pumps are often used for water watering, circumstances needing high, reputable pressure and distribution systems for communicating chocolate, bread, paint, etc.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.