Find the Best Pump for Your Chemical Processing Needs

Chemical pumps are an essential piece of equipment in several industries. They permit the safe and reliable transfer of harsh, abrasive, and other dangerous products. Chemical pumps are developed to decrease leak and exhausts, which is essential for safety and ecological factors.

Chemical pumps can be complex and substantial tools, so it is essential to pick the ideal one. Relying on your particular application, it is necessary to measure all the crucial facets of the pump prior to choosing any type of.

This blog is for your understanding of Chemical pumps, their applications, advantages, and what aspects to think about while going with the one!

What is a Chemical Pump?

Chemical pumps are created to be utilized in different markets and applications to handle and move chemicals and to be immune to corrosive and unpleasant liquids.

The types of chemical pumps consist of;

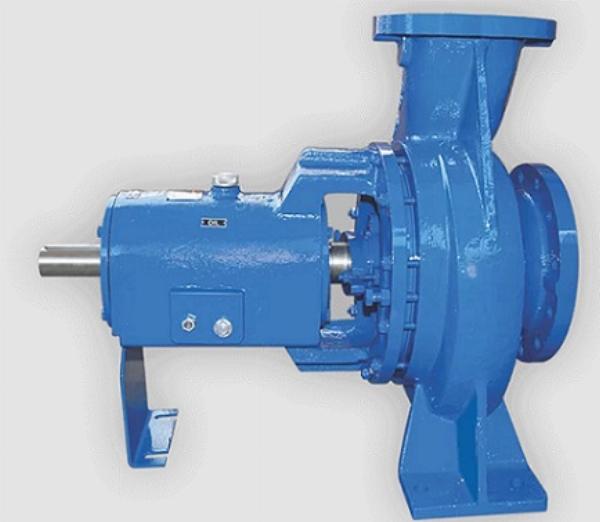

- Centrifugal pumps

- Positive variation pumps

- Magnetic drive pumps

- Submersible pumps

The type of chemical pump that is finest for a specific application depends on the specific homes of the fluid being pumped, such as its viscosity, corrosiveness, and abrasiveness.

Chemical pumps are usually made from products that are immune to the chemical being pumped. Typical products include stainless steel, polypropylene, and PTFE. The lifespan of thermic fluid pumps additionally depends on the option of materials, as high-temperature applications require durable building and construction to endure thermal stress and preserve long-lasting efficiency.

Chemical pumps have unique features such as mechanical seals to prevent leak and a cooling system to prevent the pump from overheating. A vertical centrifugal pump is an excellent choice for dealing with different chemicals in industrial applications. Its space-saving design, effective performance, and capability to handle various liquids make it a recommended choice for markets needing reliable and leak-proof pumping solutions.

How Do Chemical Pumps Work?

Chemical pumps create pressure to move a liquid or chemical from one to another location. There is no established way to create this pressure, it varies on the type of chemical pump you utilize in your applications. Majority of the chemical pumps use impellers or rotors to develop the stress to move the fluid.

The one usual type of chemical pump - Centrifugal pump uses an impeller to produce a centrifugal force. Positive displacement pumps function by capturing a certain amount of fluid in a chamber and afterwards developing a pressure to take it out of the chamber.

There are different types of pumps used in the pharmaceutical industry, consisting of centrifugal pumps for general fluid transfer, peristaltic pumps for accurate dosing, and diaphragm pumps for dealing with delicate or harsh materials.

To make it easy for you to understand, below is a simplified explanation of how chemical pumps work.

- The chemical goes into through the inlet port.

- The impeller rotates and flings chemicals in an outward direction by developing a centrifugal force.

- The forced-out liquid is gathered in volute spreading to direct it out of the pump with the outlet port.

The rate of the impeller and the size of the volute casting figure out the flow price and pressure of the pump.

Applications of Chemical Pumps

Chemical pumps have a wide range of applications. Different markets make use of ideal kinds of pumps for their particular application or needs.

We have actually listed down some common applications of Chemical pumps below:

- Chemical Manufacturing

- Water Treatment

- Cement Plants

- Paper/Pulp Production

- Pharmaceuticals

Chemical pumps play an important role in the manufacturing of a wide variety of products and the distribution of crucial solutions. These and many various other markets consider chemical pumps as crucial equipment for their everyday operations. For applications needing higher stress and effectiveness, multistage pumps for high pressure are the suitable choice.

Advantages of Using Chemical Pumps

Chemical pumps use various benefits over various other chemical moving approaches. They are sufficient adequate to boost security and minimize environmental influence.

Some common benefits of chemical pumps include:

- Energy Efficiency

Chemical pumps are designed to be power effective. It aids to conserve unneeded costs on the electrical power bills. Over any other pumping method, chemical pumps rate greater with their energy performance power.

- Corrosive Resistance

The building of chemical pumps permits them to manage unsafe products, such as acids, solvents, and caustics without triggering any kind of damage to the pump and setting about. With this capacity, chemical suppliers, suppliers, or individuals can convey a selection of fluids in different problems.

- Smooth Flow

The chemical pumps are developed to deliver a smooth and pulseless flow. The threat of destructive pipes and other equipment is minimized with the chemical pumps. These pumps stay clear of discharges and save manufacturers from investing added expenses on buying pulsation dampeners.

For applications requiring high efficiency and pressure, a multistage centrifugal pump is perfect for your needs. These pumps include several impellers to generate greater stress while preserving regular circulation, making them suitable for sectors that require precise and dependable liquid handling.

- Reliability & Security

Chemical pumps are a lot more trusted and resilient. Chemical pumps are the best remedy for the numerous pumping requirements of several markets. These pumps have high safety and security requirements. Chemical pumps work by serving reliability, safety, and longevity. Industries can rely upon chemical pumps for their long-lasting and risk-free operation.

- Reduced Maintenance

Chemical pumps are low upkeep. Pumps with high maintenance are less attractive to sectors. On the other hand, chemical pumps have low repair work prices. With chemical pumps working by sector side, specialists can collaborate with even more concentrate on their operational tasks, rather than looking for the pumps.

- Application Versatility

Chemical pumps offer their advantages in more than one sector. From chemical to food handling to water therapies to several other industries. Different sorts of chemical pumps are used in different applications to offer services based upon certain requirements.

- Cost-efficiency

Chemical pumps are reasonably economical as a result of their reduced upkeep. These pumps minimize the cost of routine maintenance and repair cost. The regularity of repairing and replacing these pumps is fairly lower than any other pumping approach.

Appropriate vertical centrifugal pump selection is important to make certain ideal performance and long life. Choosing the best pump based upon application requirements, liquid properties, and operating problems aids decrease downtime and improves overall performance.

Select the Right Chemical Pump: An Ultimate Overview

The need for chemical pumps is rapidly boosting amongst chemical industries. In order to safeguard the staff members and the environment from the damaging chemicals and acids. As a result, these centrifugal process pump manufacturers need to produce a safe setting.

Using chemical pumps varies from one to one more because of the contrasting habits of liquids. Care for the complying with factors before taking into consideration any kind of chemical pump for your applications.

1. Needed Flow Rate

The flow rate of chemical pumps have to be sufficient to meet the demands of the application. The circulation price of chemical pumps is mostly determined in gallons per minute (GPM) or litres per min (LPM).

2. Pressure Needed

The pump has to have the ability to produce enough stress to move the fluid via the system. The stress is usually in extra pounds per square inch (PSI) or bar.

3. Liquid Transfer

The picked chemical pump should work with the type of fluid being moved. Think about the kind of liquid you are moving, is it harsh? Or includes solids? Some pumps are only developed to relocate the acids, bases, and solvents.

4. Quantity of Chemical

The volume of chemicals is one essential variable to think about in choosing chemical pumps. Pick a pump that can deal with the needed quantity of chemicals without overheating.

Amongst the key factors to consider when buying a pump, circulation price, material compatibility, energy efficiency, and maintenance requirements play essential duties. Reviewing these variables helps in choosing one of the most appropriate pump for long-term performance and integrity.

5. Application Environment

The application environment of your chemical pump is of utmost relevance. Sunlight exposure on the pump, and the temperature of its installation area - maintain these in mind. Do not forget this aspect since this is a definite part of the pump's efficiency.

6. Pump Material

The pump should be made from a material that is suitable for your application. See to it your pump is made of stainless-steel, hestelloy, and PVC. Some fluids such as acids and bases can corrode the product.

7. Required Suction Lift

The suction lift is the upright range in between the fluid degree in the suction container and the pump inlet. Pick a pump that can produce the required suction lift.

Pump Up the Efficiency!

Employee safety and security and a great environment are the leading concerns for any type of sector, while also checking out the efficiency of the pump. To fulfill every one of these, you just need to care for the above elements or get in touch with a reliable supplier of chemical pumps.

A thermic fluid pump is particularly made for high-temperature applications, making certain risk-free and effective warmth transfer. Choosing a top notch thermic fluid pump enhances workplace safety and security, reduces functional risks, and enhances general system performance.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.