Guide for Install Centrifugal Pump for Your Industrial Plant

One of the most important factors in making sure that your pump system competes for years without creating regular troubles is to get the installation right. You might have picked a top-quality pump, however, without the best setup procedure, your pump is most likely to face many operational challenges.

In this guide from SMS Pumps & Engineers, a leading vertical centrifugal pump manufacturer in India, we give you all that you require to learn about centrifugal pump installation - the steps entailed, points to bear in mind, and more.

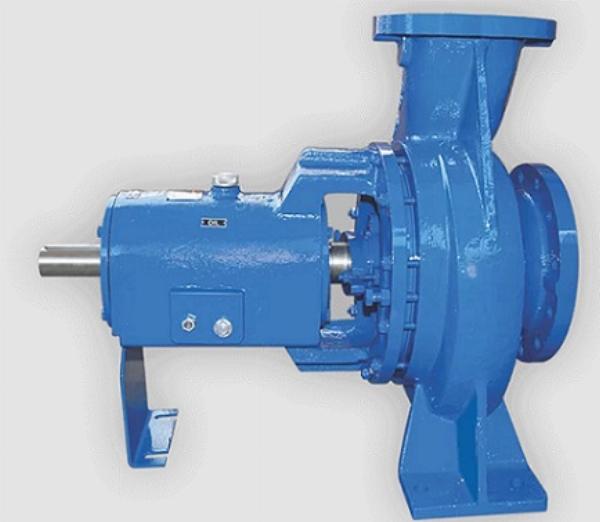

What is a Centrifugal Pump?

Centrifugal pumps are the most typically made use of pumps for transferring fluids from a low level to a greater degree. Below's the meaning of centrifugal pumps: "A centrifugal pump uses rotating impellers to present rate to a fluid. It then converts the created speed right into a flow." It's hydraulic equipment that transforms power right into hydraulic energy by creating a centrifugal force that acts upon the liquid.

To explore more about this topic, check out our related blog posts:

Identifying Common Issues and Solutions for Centrifugal Pumps

Self-Priming Pumps: Pros and Cons You Need to Know

What are the Types of Centrifugal Pumps?

Priming: Is It Necessary for Centrifugal Pumps?

Enhancing Water Supply Efficiency with Residential PumpsThe turning impeller in a centrifugal pump moves the liquid (water or other fluids) using centrifugal force. Centrifugal pumps are used in numerous sectors, like food processing, mining, oil, pharmaceutical, chemical, and numerous others.

Main Parts of a Centrifugal Pump

1. The Impeller

It's a rotor or wheel with a variety of backward curved blades (known as vanes). The impeller is mounted on a shaft that is combined with an exterior power resource. Impellers can even more be classified right into 3 types: open, semi-closed, and confined.

2. Casing

The case is a pipe whose top end is attached to the impeller's eye (center). The lower end of the casing dips into the displaced liquid, triggering it to raise the fluid. Typically, the reduced end of the housing has a foot shutoff and strainer. Casings in centrifugal vertical pumps can be divided right into volute covering, vortex housing, and a casing with guide blades.

3. Delivery Pipe

The lower end of the shipment pipe is connected to the pump outlet. The role of the shipment pipe is to carry the liquid to the called-for height. It is fitted with a shutoff that manages liquid circulation from the pump.

4. Suction Pipe

One end of the suction pipe is attached to the impeller's inlet and the other end dips into the water sump. The foot shutoff relocates only in one direction i.e., up - the filter filters out dirt, deposits, and various other waste fragments existing in the water.

To explore more about this topic, check out our related blog posts:

Agricultural Pumps: Types, Features & Solutions

Everything about Industrial Pumps in the Sugar Industry

Benefits of High Quality Industrial Pumps in Manufacturing

Everything You Need to Know About Multistage Centrifugal Pumps

Installation of Centrifugal Pumps - Steps Involved

Right here is a detailed overview of the setup of centrifugal pumps:

Step 1: Understand the Manufacturer's Instalments Instructions

All centrifugal pumps included an operation & maintenance manual. See to it to completely review the handbook before you start the installation procedure. Besides offering info on pump maintenance and operation, the manual has a comprehensive overview of setting up the pump. Guarantee that you recognize the directions before mounting the pump. Bear in mind that failing to adhere to the supplier's guidelines can lead to the voiding of the service warranty.

Step 2: Aesthetically Evaluate the Pump for any Signs of Problems

The next step is to do a thorough aesthetic inspection of the pump. You can ask the thermic fluid pump manufacturer if they have an inspection list. If yes, comply with the checklist. If not, you can ask the maker to lead you on the products you need to inspect before attempting setup.

Here are a few products to inspect:

Check if all devices appear - no leaking seals, guards are in place, electric connections are correctly terminated, etc.

Next off, look for the placement of the pump utilizing a machinist degree.

Examine lubricating substance levels and verify if the seal is appropriately set up. These are just the important assessment list. You make sure to have a lot more. The critical point here is to be detailed and thorough.

Step 3: Installation

You can either bring in a manufacturer-authorized specialist to do the setup or select your internal technicians. Besides the Installation, the service technician will accomplish other solutions like positioning inspection, resonance dimension, flatness dimension, and so on. Make sure that the professional you employ is certified to accomplish the Installation in the correct method.

Things to Keep an Eye on Throughout Centrifugal Pump Installation

Even if you employ a third-party professional to take care of the installation, you are required to watch on particular points. Here's what to try to find throughout the installation procedure:

Foundation

Industrial centrifugal pumps are big and hefty. For this reason, they need a durable foundation. Make sure that the structure on which the centrifugal pump is installed is hard enough to support the rest of the unit. The screws used in the foundation should be of the ideal size and ingrained well right into the concrete. Use a pipeline sleeve that is larger than the screw.

Mounting

The base of the pump needs to be levelled to make sure that the pump shaft is vertically straightened. The suction pump should be placed vertically, while the discharge flanges are placed flat.

Field Alignment

Make sure that there is sufficient spacing between the combining halves' faces to make sure that they do not strike each other. The coupling halves are likely to strike each other when the chauffeur blades are moved facing the pump.

Piping

Make sure that discharge and suction pipelines are sustained separately utilizing assistance blocks and pipe wall mounts. This avoids extreme pressure on the casing and joints of the pump system. The alignment of the pipe must be checked before a connection is produced.

Electrical wiring

The electrical wiring utilized in the pump system needs to be of ample size to prevent voltage drops. Make sure that the pump is not started prematurely until it is loaded with the fluid.

Rotation

The orientation of the turning of the centrifugal pump is mentioned in the covering. Make sure that the pump is dealt with in the appropriate turning direction, before assembling the coupling on the base.

Priming

The pump's suction line ought to be filled gradually with the liquid up until a stable circulation is created. Make certain that you open the air vent to eradicate all air from the case.

Conclusion

We extremely encourage you to comply with the manufacturer’s directions at every action. The centrifugal process pump manufacturer is responsible for developing and creating the pump equipment. Thus, they are more aware of the system's capacities and level of sensitivity and handle the warranty stipulation against problems. You must maintain the warranty undamaged so you can make cases versus any manufacturing flaws if present.

When you have adhered to the right installation steps, you can relax understanding that your centrifugal pump awaits operation and will certainly run for years to find. SMS Pumps & Engineers are among the top centrifugal chemical pump manufacturers in India. We provide a wide variety of commercial pumps for all industries.

To explore more about this topic, check out our related blog posts:

All You Need to Know About Multistage Centrifugal Pump

What are the Types of Pumps use in the Pharmaceutical Industry?

What You Need To Know About Vertical Multistage Pumps?

Key Considerations for Restarting Centrifugal Pumps

A Roadmap to Extending Chemical Pump Lifespan

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.