How Sheet Metal Design Drawings Services Contribute to Better Lean Manufacturing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

Lean manufacturing continues to gain momentum in the AEC industry, especially among architects and engineers who are under pressure for faster production schedules, want to reduce waste, and require shorter delivery time frames. When companies seek to streamline their metal fabrication process without compromising quality or delivery schedules, they often overlook a hidden enabler of value: Sheet Metal Design Drawings Services. Sheet metal technical drawing services are typically relegated to background support. However, they are the foundation of how the best fabrication shops and the most innovative companies establish a production strategy that captures the essence of lean thinking.

In this blog, I will explore how properly organized drawing services nestle at the heart of the lean manufacturing mindset. While customizing standards, prioritizing clear purpose and objectives, workflow readiness, and strategic planning, the drawing services have a significant impact on the value stream as a whole, from engineering to delivery.

Understanding Lean Manufacturing from a Metal Fabrication Perspective

A. The Principles That Matter in Fabrication

Lean manufacturing is more than just removing excess. It’s about building workflows that move without pause, where output is predictable, waste is visible, and decisions are fast. In sheet metal environments, this means knowing exactly what to build, when to build it, and how the components behave once installed.

B. Translating Lean into Engineering Practices

For engineers working on metal systems, time isn’t just money—it’s relevant. If a fabricator waits for interpretation or clarification, the system begins to slow. That’s where Sheet Metal Drafting Services begin to show their practical value. Instead of treating drawings as static diagrams, they become engineered instructions with real-time manufacturing logic.

Improving Manufacturing Accuracy with Drawing Services

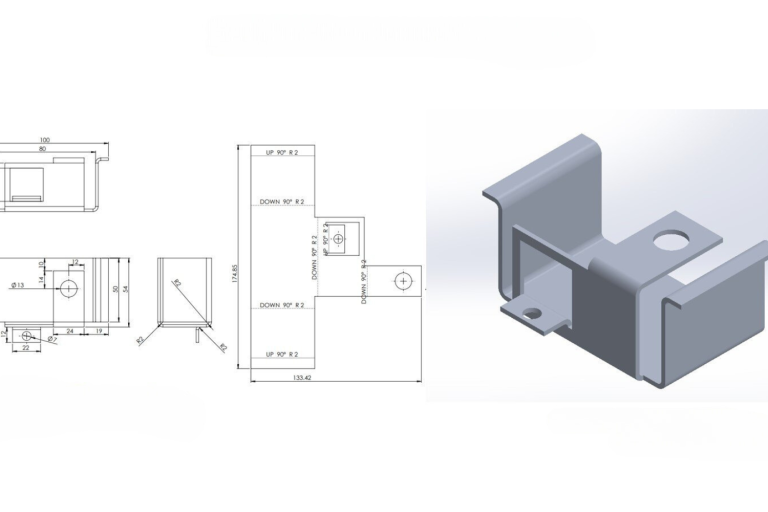

A. Clarity Before Cutting

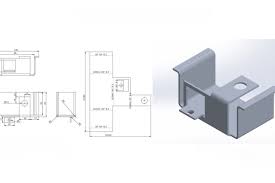

Without design clarity, the production line becomes a sequence of assumptions. Sheet Metal Engineering Drawing Services help establish readiness well in advance of fabrication. Design layouts become more than marks on paper—they tell a story. They define part behavior, mating relationships, and even folding directions.

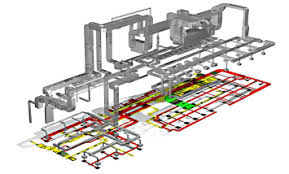

B. From CAD Design to Floor Action

When companies transition to lean frameworks, the evolution from idea to machine encounter should not include unnecessary detours. The transition from CAD to production is not as disorderly if a company adopts SolidWorks Sheet Metal Drawing Services. 3D-based modeling enables seamless communication with press brakes, laser cutting machines, and stamping machines, eliminating uncertainty and the need for test runs.

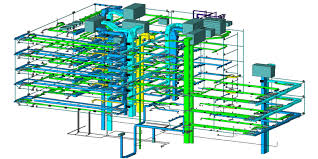

C. Nesting Drawings with Assembly Logic

No drawing should exist in isolation. Nested designs help define how small parts become final assemblies. Sheet Metal Fabrication Drawing processes contribute by bundling detailed views, revision tracking, and tolerance schemes in a way that supports the actual build sequence.

Waste Elimination

A. Avoiding Rework from Day One

Rework begins when drawings demand interpretation. It multiplies when shop floor teams spend more time asking questions than building components. By front-loading clarity, Sheet Metal Design Drawings Services shift the burden of accuracy from the fabrication phase to the design phase, thereby enhancing overall accuracy and reliability.

B. Material Movement Without Delay

In lean setups, material waits are a significant cause of delay. However, when drawing services communicate movement paths, bending operations, and stock thicknesses early on, material handling becomes a crucial aspect of the design conversation. Sheet Metal Drafting Services simplify layouts so that logistics don’t block productivity.

C. Layouts That Support Visual Manufacturing

Well-developed engineering drawings contribute to lean visual systems. With diagrams that speak clearly—often visually instead of descriptively—operators don’t require long instructions. Instead, views, dimensions, and part callouts offer visibility into part function, orientation, and even inspection requirements.

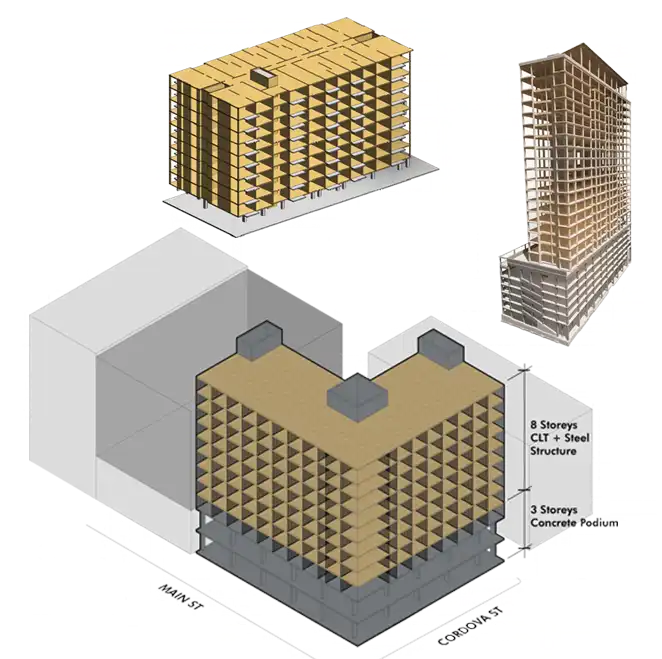

Scaling Lean: Drawing Services in Modular and Repetitive Fabrication

A. Applying Lean to High-Mix, Low-Volume Fabrication

The real test of lean principles isn’t in mass production—it’s in setups where parts constantly change. That’s where Sheet Metal Engineering Drawing Services can be customized per assembly. Modular breakdowns enable engineers to reuse logic and maintain drawing integrity even when variables change.

B. Drawing Libraries for Repetitive Use

Repetition without repetition—that’s lean. Drawing libraries created through SolidWorks Sheet Metal Drawing Services facilitate easier reuse. Whether it’s HVAC ducting or panel brackets, a modular approach to drawing reuse limits time spent on redesigning and redrawing. These libraries help avoid inconsistent drawings for the same components.

C. Adaptable Drawing Standards for Global Teams

Today’s engineering teams are scattered across borders. Lean thinking requires that drawings speak the same technical language across locations. Sheet Metal Fabrication Drawing practices allow for that consistency—especially when libraries follow fixed templates, legends, layer structures, and view scales.

Design for Lean Fabrication: What Drawing Services Enable

A. Drawings That Reflect Machine Behavior

Instead of sending raw designs to the floor, a lean setup encourages drawing practices that factor in machine limitations. That means identifying bend allowances, flat patterns, and tool-specific notches. With Sheet Metal Design Drawings Services, design becomes an extension of equipment capability.

B. Tolerance Thinking From the Start

Lean systems don’t welcome trial and error. From the earliest engineering stage, tolerances have to be measurable and relevant. Instead of vague approximations, Sheet Metal Engineering Drawing Services document real allowances, stack-ups, and part fitment logic that hold up in practice.

C. Simultaneous Design and Planning

Most companies view design and planning as two distinct steps. In lean systems, drawing services let both coexist. As drawings are created, planning elements—such as cutting strategy, machine orientation, and inspection benchmarks—are incorporated. Sheet Metal Drafting Services support this integrated approach.

From Paper to Performance: Measuring Drawing-Driven Outcomes

A. Fabrication Accuracy through First-Time Fit

When drawings clearly express the final intent, the result is a component that fits without modification. This accuracy is often attributed not to better machinery, but to better drawing logic—such as what’s produced by SolidWorks Sheet Metal Drawing Services.

B. Assembly Without Guesswork

When drawings leave no ambiguity, teams don’t spend time second-guessing hole placements, bend directions, or weld symbols. Components flow into place. Sheet Metal Fabrication Drawing approaches that focus on coordinated callouts and sequencing help remove unnecessary decision-making from the shop floor.

C. Shorter Feedback Loops from Floor to Engineering

With more precise drawings, errors aren’t masked—they’re caught early. When fabricators and engineers operate off the same base logic, revisions become more constructive. Sheet Metal Design Drawings Services enable production teams to provide contextual input, not just complaints.

Conclusion

Sheet Metal Design Drawings Services aren’t simply technical documentation—they’re manufacturing instructions with business consequences. When these drawings evolve to reflect lean values, they begin to influence planning speed, material usage, and on-floor behavior.

AEC professionals, engineers, and production managers must shift their perception of these services—from background task to core strategy. It’s through detailed, logic-driven drawings that lean becomes more than a philosophy. It becomes practice.

By connecting fabrication logic with drawing output, businesses can unlock a cleaner path from concept to assembly. And in a competitive world where manufacturing agility often wins contracts, that shift can make all the difference.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.