Why Mass Timber Design Services Are Not Only About Woodwork Drawing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Mass timber is not only about wood. While the material draws attention for its warmth and appearance, the real substance of mass timber construction lies much deeper. This blog explores how Mass Timber Design Services focus on the shapes, joints, and thinking behind a timber building—not just the material itself. It breaks down why geometry matters, how assembly methods shape design, and where sustainability decisions begin. AEC professionals seeking to use Structural Timber Design Service or Mass Timber Architecture Services will find this blog helpful to better understand the design thinking involved. Every section points to the real demands of timber design and the larger process around it. The blog covers not only design ideas but also how Mass Timber Drawings Services and Mass Timber 2D Drawings Services build technical clarity and construction value.

I. Understanding Mass Timber Beyond Surface Material

A. The Structure Is the System

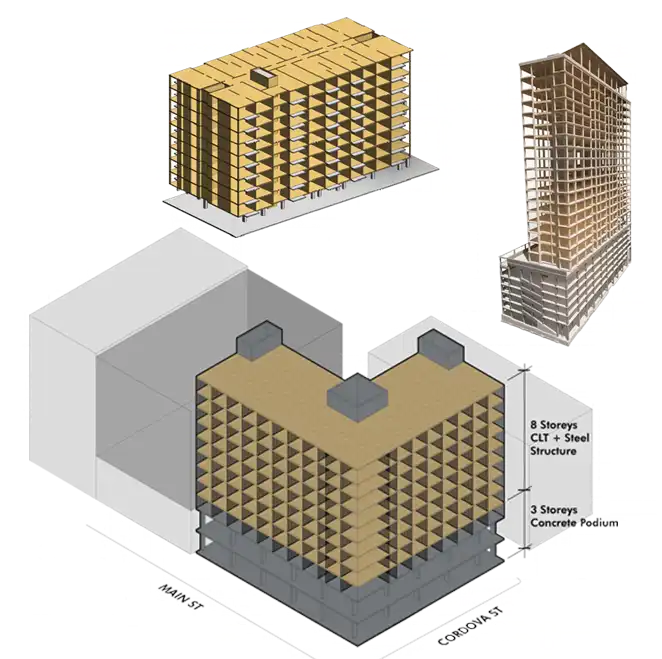

Mass timber buildings depend on their structural behavior. Loads move through beams, panels, and posts. Shapes matter. Forces do not bend wood the same way as steel. This shifts early layout logic. Mass Timber Design Services focus on spacing, span length, and depth. A designer needs to picture the frame before placing a wall. It is not about wrapping wood around a space. It is about forming the space with wood.

Structural Timber Design Service often starts with span-to-depth ratios. A thicker panel changes head height. A deeper beam changes daylight access. These decisions happen before the wood type. It starts with shape.

B. Geometry Directs Possibility

Grids affect movement and walls. Panel dimensions affect direction. A two-way slab logic does not apply in most mass timber. Mass Timber Architecture Services calculate the impact of panel direction and beam interruption. Geometry also affects acoustics. A continuous surface can cause echoes. Mass Timber 2D Drawings Services show these impacts at an early phase. They help avoid performance setbacks later.

Angles also change load behavior. Straight-line thinking does not always work in timber. Geometry forms the rhythm of mass timber structures. Square rooms, linear beams, and balanced spacing work better than complex curves.

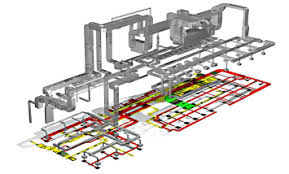

C. Geometry Is Not Just Form

It helps sequence actions. It helps package parts. It also helps plan crane lifts. It decides transport loads. Geometry also shapes fire separation zones. Mass Timber Drawings Services do more than show dimensions. They reflect logic. AEC professionals can plan faster when geometry stays thoughtful.

II. Assembly as a Design Language

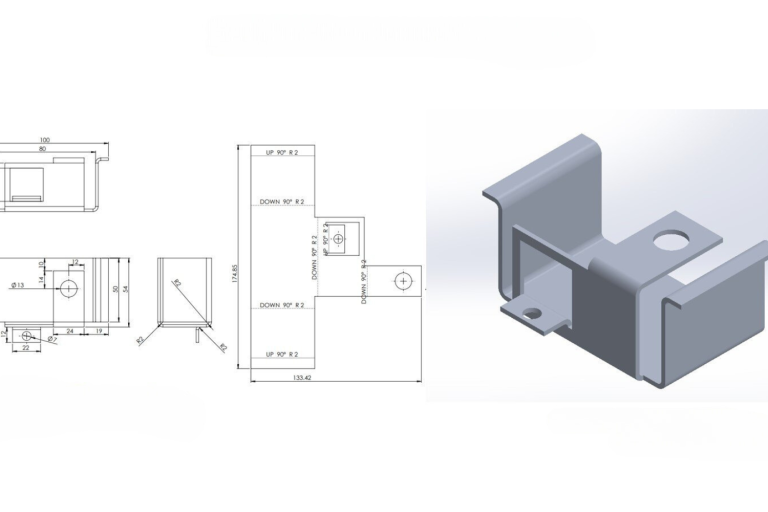

A. Joint First, Volume Later

Mass timber assembly starts with connections. Timber cannot bend into shape on site. Pre-set joints must fit. Connection methods shape layouts. Structural Timber Design Service works backward from assembly. The placement of a hidden bolt decides beam width. Nail-laminated or dowel-laminated systems change joinery space. These inputs come before aesthetics.

Mass Timber Design Services use this thinking to plan wall-floor transitions. Clashes happen when joinery is ignored. Without early joint planning, surfaces misalign.

B. Assembly Dictates Transport and Staging

Panels have width limits. Lifts have turn radii. Glulam beams bend under self-weight. Design must fit the lifting logic. This makes assembly part of the early design. Mass Timber 2D Drawings Services often reflect hoisting paths. They inform which element gets placed first.

Every hoist affects the sequence. Assembly affects labor planning. Panel sizes affect staging zones. AEC professionals reviewing Mass Timber Drawings Services will spot these elements. A drawing is more than lines. It holds logic for how a building grows on site.

C. Layering Instead of Stacking

Mass timber design avoids vertical confusion by planning interfaces. It builds on layering principles. Walls meet floors with a reveal. Roof decks overhang for drainage. Assembly uses these overlaps to make work easier on site. These overlaps must exist in the design phase.

Mass Timber Architecture Services use these overlaps as part of the visual design. They appear in facade details and overhangs. Mass Timber Design Services rely on clear section logic to make layering easy to read.

III. Sustainability Starts at the Layout Stage

A. Not Just Carbon

Mass timber attracts attention for its carbon profile. But real sustainability begins earlier. Layouts that avoid waste perform better. Panel cuts cost more in material. Structural Timber Design Service looks at grid spacing that fits panel modules. A 9-meter span wastes less than 8.7 meters. Matching standard lengths leads to less scrap.

Mass Timber Design Services avoid layout improvisation. They plan dimensions that match supply. This avoids waste before cutting begins.

B. Thermal Performance by Section Planning

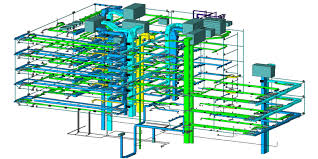

Exposed timber needs protection. Walls must hide insulation without extra framing. Roofs must carry loads while managing heat. Section planning decides all this. Mass Timber Architecture Services use floor and roof layering to meet these needs. The arrangement affects performance.

Mass Timber 2D Drawings Services include cavity zones and air gap alignment. These zones shape energy performance. Good layout means fewer overlaps. It helps building shells work better in all climates.

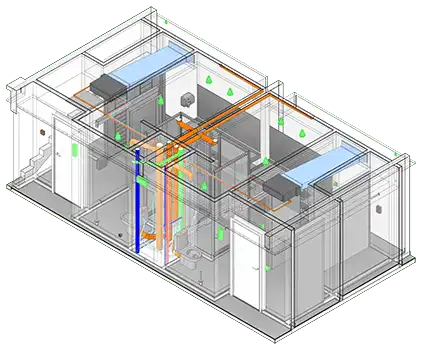

C. Air, Light, and Assembly Logic

Large openings matter for indoor health. Timber panels limit opening sizes. Assembly affects what opens and where. Mass Timber Design Services plan around these fixed panel sizes. They make daylight a shape question, not just a material decision.

Geometry also affects air paths. Ventilation planning happens in parallel with the structural layout. Openings sit where panels permit. Mass Timber Drawings Services reflect this cross-check between structure and indoor health.

IV. Mass Timber Drawings as a Planning Map

A. Drawings Reflect Assembly Logic

Drawings for mass timber are not just technical packages. They describe the idea behind the building's form. Mass Timber 2D Drawings Services include part breaks, fastener types, and panel joinery. These drawings help form a mental picture of how the building stands.

Mass Timber Design Services give details that shape daily site actions. Beam pocket size affects wall thickness. Plate size changes the plinth depth. Drawings carry real-world results in every dimension placed.

B. Plans Must Tell a Story

AEC teams read drawings like books. Mass Timber Drawings Services must read from grid to panel. They must show where one part ends and another begins. Clarity allows the site team to act with purpose.

Plans also reflect geometry. Mass Timber Architecture Services create floor plans that help connect elevations and sections. This three-layer reading helps people understand how everything fits.

C. Assembly Steps in Elevation

Drawings often carry a flat look. But in mass timber, elevation matters. A section drawing must show who comes first—the floor or the beam. Assembly logic depends on it. Mass Timber 2D Drawings Services label not just parts, but order. Elevations should show flow.

Mass Timber Design Services depend on smart sequencing of these layers. When a wall meets a roof, timing matters. The drawing must speak that timing.

V. A Mindset Change for AEC Professionals

A. Think Sequence, Not Object

Mass timber thinking requires sequencing at the start. It is not a matter of placing shapes. It is about arranging actions. Mass Timber Design Services apply this thinking across all phases.

AEC professionals benefit when they look at parts as steps, not items. Geometry, joint type, lifting path, and insulation meet in one view.

B. Think Assembly as Design, Not Delivery

Mass Timber Architecture Services do not separate design from process. When a designer draws a floor panel, they also define the install step. Mass Timber Drawings Services show how things fit—but also how actions line up. The building becomes an instruction, not just a form.

Structural Timber Design Service follows this same thinking. Panel weight affects layout. Beam orientation affects lighting. Nothing happens by accident.

C. Think Sustainability as a Drawing Problem

Material quantity links to drawing decisions. Layout grids create waste or avoid it. Wall assembly planning shapes thermal loss. Mass Timber 2D Drawings Services help reveal these performance factors early.

Mass Timber Design Services, when read correctly, let professionals build with less friction and more purpose. It starts not from the wood, but from the choices around it.

Conclusion

Mass timber design holds more than its surface. The way geometry fits, the way joints meet, and the way assembly flows all form the real language of mass timber buildings. This is what Mass Timber Design Services aim to show. Structural Timber Design Service and Mass Timber Architecture Services all work together toward buildings that do more with shape, planning, and clarity.

AEC professionals who use Mass Timber 2D Drawings Services well will not only visualize structure. They will plan actions. They will shape outcomes that match the original design goal. And that is what makes timber design not just about wood—but about thoughtful geometry, clear assembly, and grounded sustainability.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.