On-Page SEO Optimization – Fix Hidden Errors Killing Rankings!

On-Page SEO Optimization – Fix Hidden Errors Killing Rankings!

Rotary Supporting Bearings: Everything You Need to Know

Written by qianas » Updated on: June 17th, 2025 89 views

When it comes to precision machinery and industrial applications, rotary supporting bearings play a crucial role in ensuring smooth and efficient operations. Whether you’re dealing with heavy-duty machinery, robotics, or high-speed manufacturing systems, these bearings provide the necessary support to handle loads and maintain rotational accuracy.

What Are Rotary Supporting Bearings?

Rotary supporting bearings are specialized components designed to support rotary motion while minimizing friction and wear. These bearings enhance the performance and lifespan of mechanical systems by allowing smooth rotation and reducing energy losses. They are commonly found in rotary tables, CNC machines, wind turbines, and robotic arms.

Types of Rotary Supporting Bearings

Choosing the right rotary supporting bearing depends on factors such as load capacity, speed, and environmental conditions. Here are the most commonly used types:

1. Slewing Bearings

Slewing bearings, also known as turntable bearings, are designed for heavy axial, radial, and moment loads. They are widely used in excavators, cranes, and wind turbines where smooth, large-scale rotation is essential.

2. Cross Roller Bearings

These bearings offer high rigidity and precision, making them ideal for robotic joints, medical equipment, and machine tool spindles. The crossed roller design allows them to withstand both radial and axial forces efficiently.

3. Thrust Ball Bearings

Thrust ball bearings handle axial loads efficiently and are commonly used in high-speed rotary applications, such as automotive steering systems and industrial turbines.

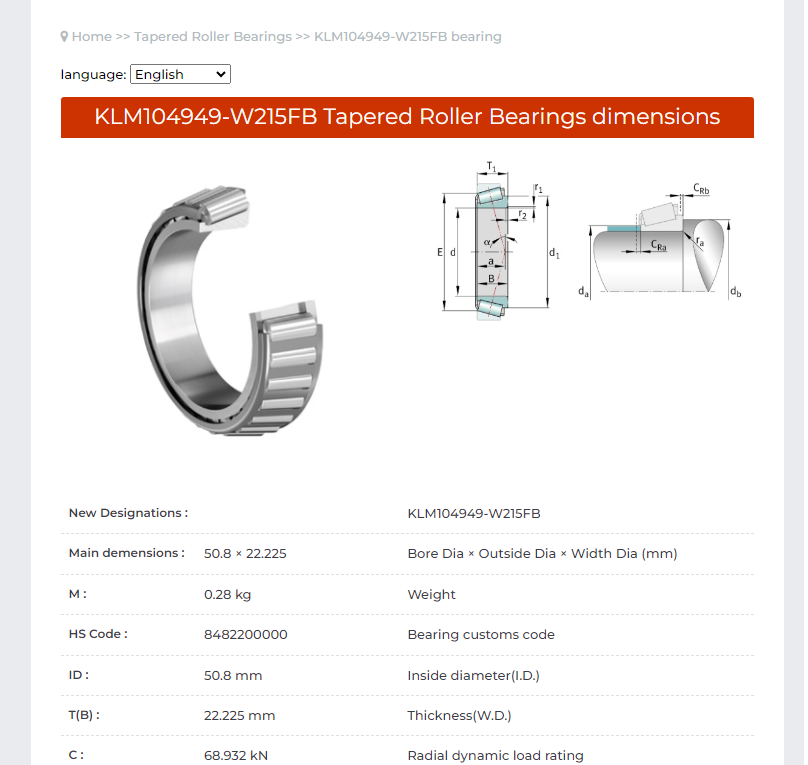

4. Tapered Roller Bearings

These bearings are excellent for applications requiring high load capacity and durability, such as gearboxes, agricultural machinery, and rail transport.

Benefits of Rotary Supporting Bearings

Using rotary supporting bearings brings numerous advantages to industrial and mechanical applications. Here’s why they are essential:

Enhanced Durability: Designed to withstand high loads and harsh environments.

High Precision: Crucial for applications requiring accurate and stable rotation.

Reduced Friction: Minimizes energy loss and prevents overheating.

Increased Efficiency: Optimizes the performance of CNC machines, turbines, and automation systems.

Applications of Rotary Supporting Bearings

These bearings are versatile and are found in a wide range of industries, including:

Aerospace & Defense: Ensuring precision in aircraft and military equipment.

Automotive: Supporting high-speed rotation in engines and transmissions.

Manufacturing: Providing stability in CNC machining and robotics.

Renewable Energy: Enhancing performance in wind turbines and solar trackers.

How to Choose the Right Rotary Supporting Bearings

Selecting the right rotary supporting bearing depends on key factors such as:

Load Requirements: Determine whether the application involves axial, radial, or combined loads.

Speed & Precision Needs: High-speed applications demand low-friction and precision bearings.

Operating Environment: Consider exposure to dust, moisture, or extreme temperatures.

Lubrication & Maintenance: Proper lubrication extends bearing life and improves performance.

Where to Buy High-Quality Rotary Supporting Bearings

If you're looking for reliable and high-performance rotary supporting bearings, TradeBearings.com is a great resource. They offer a wide range of industrial-grade bearings suitable for various applications, ensuring durability and efficiency.

Final Thoughts

Rotary supporting bearings are a fundamental component in modern machinery, ensuring precision, efficiency, and longevity. Whether you need them for industrial automation, aerospace, or renewable energy, choosing the right type will maximize performance and reliability. Always consider load capacity, speed, and environmental conditions when selecting the best bearing for your needs.

By understanding their importance and applications, you can make informed decisions that enhance the efficiency and lifespan of your equipment.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.