The Backbone of Safety: Vital Lockout Tagout Devices Every Facility Needs

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

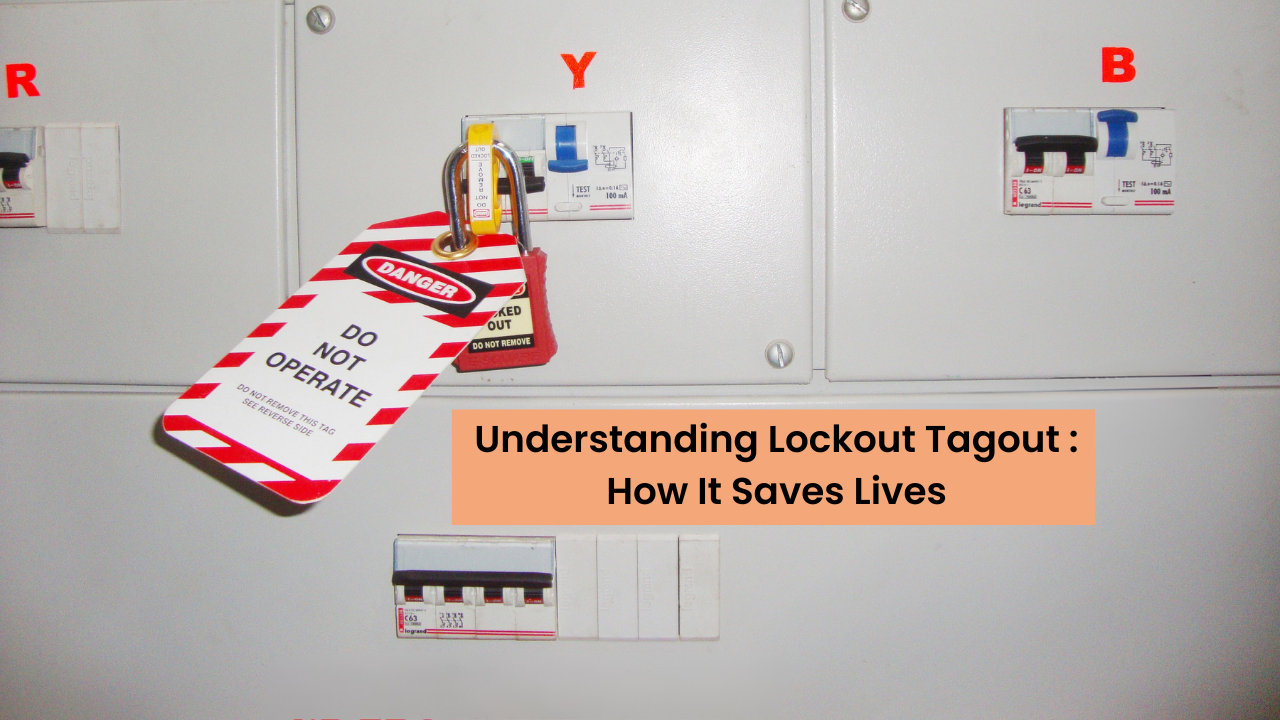

In workplaces where machines and energy systems are integral to daily operations, one mistake during maintenance can lead to life-threatening consequences. Accidental machine start-ups or the unexpected release of hazardous energy during servicing are among the leading causes of serious workplace injuries and fatalities. To combat these risks, the Lockout Tagout system has become a global standard for energy isolation and worker protection.

At the heart of every effective LOTO program lies the right set of devices. These tools form the backbone of safety, ensuring machines are properly de-energized and cannot be restarted until the work is completed. Understanding which lockout tagout devices are essential and how to use them effectively can significantly reduce risk and enhance safety across any facility.

Why LOTO Devices Matter?

LOTO devices are designed to physically prevent the operation of energy-isolating equipment, such as switches, valves, and breakers. Combined with tags that communicate warnings, these devices provide a comprehensive system for locking out machinery and ensuring only authorized personnel can restore power. Not only do these devices save lives, but they also help facilities comply with regulations like OSHA’s 29 CFR 1910.147, which mandates energy control programs in workplaces.

Essential Lockout Tagout Devices Every Facility Should Have:

Whether you’re managing a manufacturing plant, processing facility, or energy station, here are the essential LOTO devices every workplace needs:

1. Lockout Padlocks

Padlocks are at the core of any Lockout Tagout system. Unlike standard locks, safety padlocks are uniquely keyed and often non-conductive, preventing electrical hazards. Each padlock is assigned to an individual worker, and only that person can remove it - ensuring clear responsibility and personal safety.

Key features to look for:

- Non-conductive materials (nylon, plastic)

- Durable body and shackle

- Color coding for identification

- Unique key systems (keyed different, keyed alike, or master keyed)

2. Lockout Hasps

Lockout hasps allow multiple workers to apply their padlocks to a single isolation point. This ensures that a machine cannot be re-energized until all maintenance personnel have completed their tasks and removed their individual locks.

Applications:

- Group maintenance

- Team-based shutdowns

- Equipment with shared energy sources

3. Valve Lockout Devices

Valve lockout devices control the flow of hazardous liquids and gases. Locking out valves ensures they cannot be turned on during servicing.

Common types include:

· Ball valve lockouts - secure quarter-turn valves in the off position.

· Gate valve lockouts - cover and restrict access to large handwheels.

· Butterfly valve lockouts - clamp and immobilize the handle.

These devices are vital for chemical plants, oil and gas operations, and any industry using pressurized systems.

4. Circuit Breaker Lockouts

Electrical systems pose significant risks if not properly isolated. Circuit breaker lockouts prevent breakers from being switched back on during electrical maintenance. They come in various types to accommodate miniature, standard, and high-voltage breakers.

Benefits:

· Prevents arc flash incidents

· Ensures circuit integrity during repairs

· Compatible with most panel types

5. Lockout Tagout Tags

Tags complement physical lockout devices by communicating critical information. They typically include the worker’s name, department, and reason for lockout. Tags are often brightly colored and made from tear-resistant materials.

Use tags to:

· Indicate maintenance is in progress

· Prevent unauthorized removal of devices

· Ensure visibility and accountability

6. Lockout Stations and Kits

To ensure quick and organized access to lockout equipment, facilities should use lockout stations or portable kits. These centralized solutions help keep devices in one place and promote consistent LOTO procedures across teams.

Conclusion

Lockout Tagout is not just a safety procedure - it’s a safety culture. The devices that support this system are the tangible tools that protect workers, prevent costly downtime, and ensure compliance with industry standards. From padlocks and hasps to valve lockouts and breaker devices, each component plays a vital role in maintaining a safe and efficient work environment.

No matter the size or type of facility, having the right LOTO devices in place and ensuring they are used correctly - is a non-negotiable step in building a safer workplace. Because when it comes to hazardous energy, prevention isn't optional, it's essential.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.