Understanding Lockout Tagout: How It Saves Lives

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In industrial workplaces, where heavy machinery, electrical systems, and complex equipment are the backbone of operations, safety is paramount. One of the most critical safety practices in these environments is Lockout Tagout, a procedure designed to protect workers from hazardous energy sources. By ensuring that equipment is properly de-energized and secured during maintenance or repair, LOTO prevents accidents that could result in severe injuries or fatalities. Explore what Lockout Tagout is, how it works, and why it’s a lifesaver in high-risk industries.

What is Lockout Tagout?

Lockout Tagout is a safety protocol used to control hazardous energy in workplaces, particularly during maintenance, servicing, or repair of machinery and equipment. Hazardous energy can come in various forms, including electrical, mechanical, hydraulic, pneumatic, chemical, or thermal. If not properly managed, these energy sources can cause catastrophic accidents, such as electrocutions, burns, crush injuries, or amputations.

The LOTO process involves two key components: lockout and tagout.

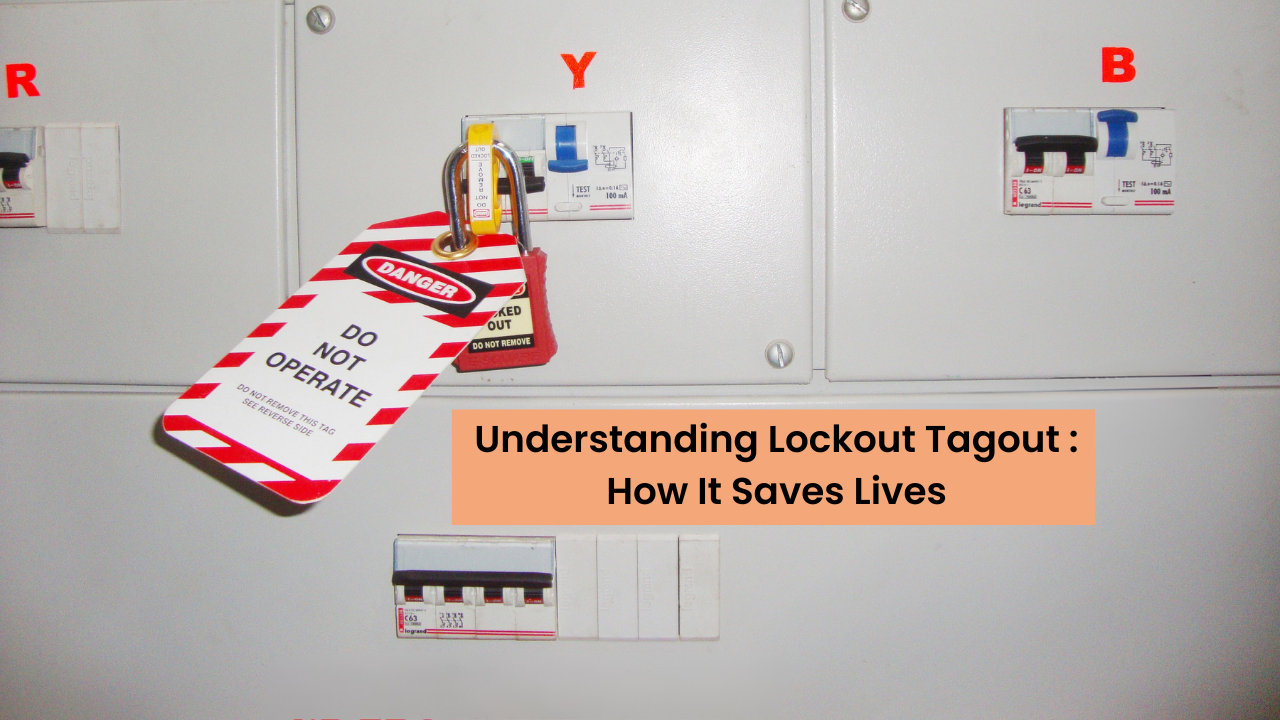

Lockout refers to physically securing an equipment with an energy isolating device (such as a circuit breaker, valve, or disconnect switch) and applying a lock to prevent the release of hazardous energy. This ensures that the equipment cannot be powered on until the lock is removed by the authorized worker.

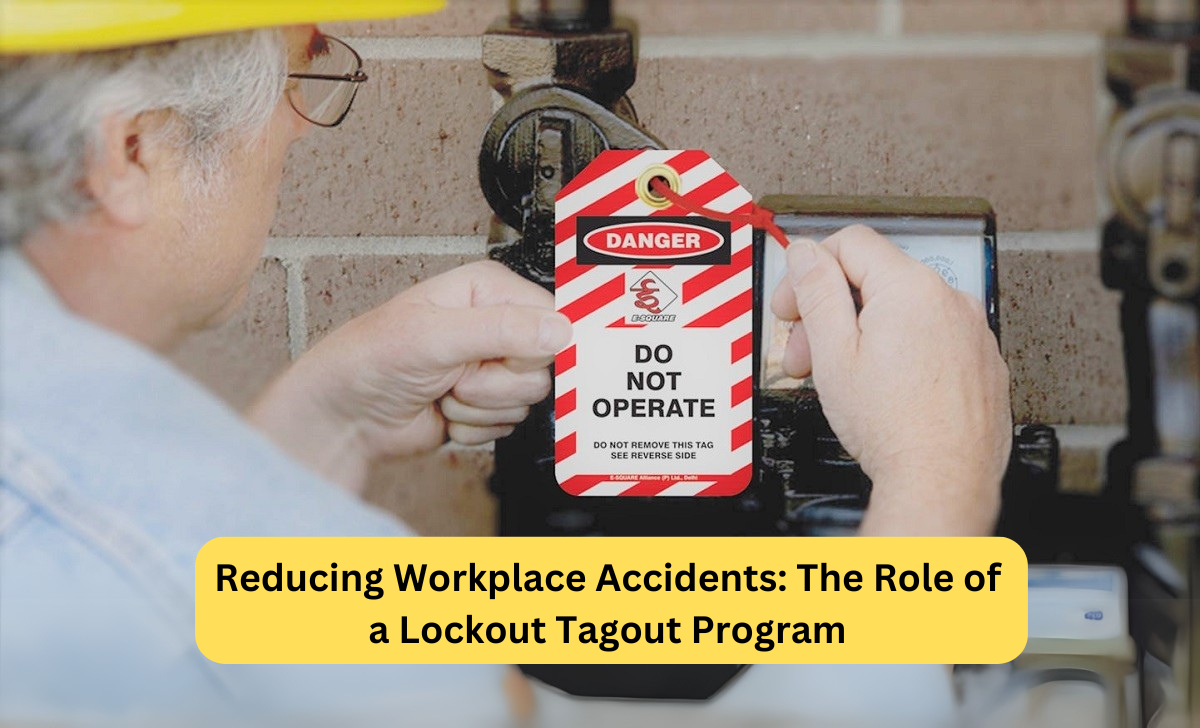

Tagout involves attaching a warning tag to the lockout device. The tag provides critical information, such as the name of the worker performing the maintenance, the reason for the lockout, and a warning not to operate the equipment. Together, locks and tags create a clear, visible barrier that communicates the equipment’s status and prevents accidental startup.

How Does Lockout Tagout Work?

Implementing LOTO involves a systematic approach to ensure safety. The typical steps include:

Preparation: Identify all energy sources associated with the equipment, including secondary sources like residual pressure or stored energy.

Notification: Inform affected employees that the equipment will be shut down for maintenance.

Shutdown: Turn off the equipment using its standard controls.

Isolation: Locate and isolate all energy sources, such as by switching off circuit breakers or closing valves.

Lockout and Tagout: Apply locks and tags to the energy-isolating devices to secure them in the “off” or “safe” position.

Release Stored Energy: Drain, discharge, or relieve any residual energy, such as pressure in pipes or capacitors.

Verification: Confirm that the equipment is fully de-energized and safe to work on, often using testing devices.

Maintenance: Perform the necessary repairs or servicing.

Removal of LOTO Devices: Once work is complete, ensure all tools and personnel are clear, notify affected employees, and remove locks and tags to restore energy.

Only authorized personnel, trained in LOTO procedures, are permitted to perform these steps, ensuring consistency and safety.

How Lockout Tagout Saves Lives:

The importance of LOTO cannot be overstated. According to the Occupational Safety and Health Administration (OSHA), failure to control hazardous energy accounts for nearly 10% of serious workplace accidents in the United States. These incidents result in thousands of injuries annually, including fatalities, electrocutions, amputations, and severe burns. LOTO directly addresses these risks by eliminating the possibility of unexpected equipment startup.

For example, imagine a worker servicing a conveyor system without LOTO. If a colleague unknowingly activates the system, the worker could be caught in moving parts, leading to catastrophic injury. LOTO prevents this by ensuring the system is locked and tagged, making it impossible to energize until the worker completes the task and removes the lock.

Beyond preventing injuries, LOTO fosters a culture of safety. It empowers workers to take control of their environment, encourages clear communication, and reinforces the importance of following protocols. Compliance with standards like OSHA’s 1910.147 also protects businesses from costly fines, legal liabilities, and reputational damage.

Challenges and Best Practices:

While LOTO is highly effective, its success depends on proper implementation. Common challenges include inadequate training, lack of clear procedures, or failure to use appropriate devices. To overcome these, businesses should:

Provide Comprehensive Training: Ensure all employees get training to understand LOTO procedures and their roles during LOTO.

Use Quality Devices: Invest in durable locks, tags, hasps and other LOTO devices that meet industry standards.

Conduct Regular Audits: Periodically review LOTO programs to identify and address gaps.

Customize Procedures: Tailor LOTO processes to specific equipment and workplace conditions.

Conclusion:

Lockout Tagout is more than a regulatory requirement - it’s a lifeline for workers in hazardous environments. By controlling dangerous energy sources, LOTO prevents accidents, saves lives, and promotes a safer, more compliant workplace.

Investing in proper LOTO training, equipment, and procedures is an investment in human lives and operational success. Whether you’re in manufacturing, construction, or energy, embracing Lockout Tagout is a critical step toward a safer tomorrow.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.