The Role of Expert Mould Drafting Services in Achieving Design Accuracy

Design accuracy is not just a technical requirement—it is the backbone of efficient mould manufacturing. Whether for plastic injection, die casting, or complex tool assemblies, every successful mould starts with a precise and well-executed drafting plan. Mould Drafting services provide the critical link between design and production, translating conceptual ideas into clear, manufacturable drawings. These detailed drafts form the blueprint from which moulds are created, leaving no room for ambiguity or error.

Rather than simply creating drawings, expert drafting professionals offer a blend of engineering insight, CAD expertise, and attention to standards. With accurate drafting, manufacturers can avoid costly reworks, ensure a smoother production flow, and achieve higher quality end products. Expertly prepared drafts not only represent physical dimensions but also include specifications like material details, tolerances, parting lines, cooling channels, and ejection mechanisms, making them indispensable in precision tooling environments.

Why Accuracy Matters in Mould Drafting

In mould manufacturing, even the slightest deviation from specifications can have significant consequences. Inaccurate drafts may lead to improper fit, flash formation, warping, or tool failure during operation. This is especially crucial in high-volume production where defects translate to material loss and financial impact. With expert mould drafting services, each feature is calculated and verified to ensure structural integrity and manufacturing feasibility. Detailed sectional views, annotations, and geometric tolerances enable seamless coordination between designers, machinists, and quality control teams.

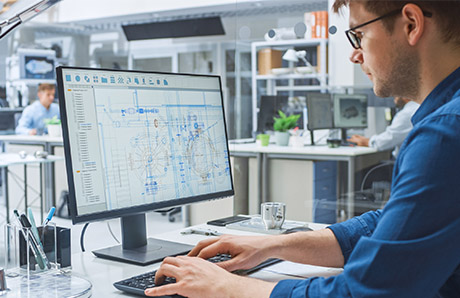

Advanced Tools Behind Precision Drafting

Modern mould drafting relies on sophisticated CAD software like SolidWorks, AutoCAD, Siemens NX, and CATIA to deliver precision and clarity. These tools support 2D and 3D drafting, allowing for multiple views, exploded diagrams, and interactive layouts. Using such platforms, drafters can simulate real-world fit and performance, identify clashes, and refine designs before physical manufacturing begins. This digital-first approach dramatically reduces prototyping costs and shortens development timelines.

Services That Go Beyond Just Drafting

Professional service providers like As Industries go beyond basic drawing creation. Their full suite of mould-related drafting services may include:

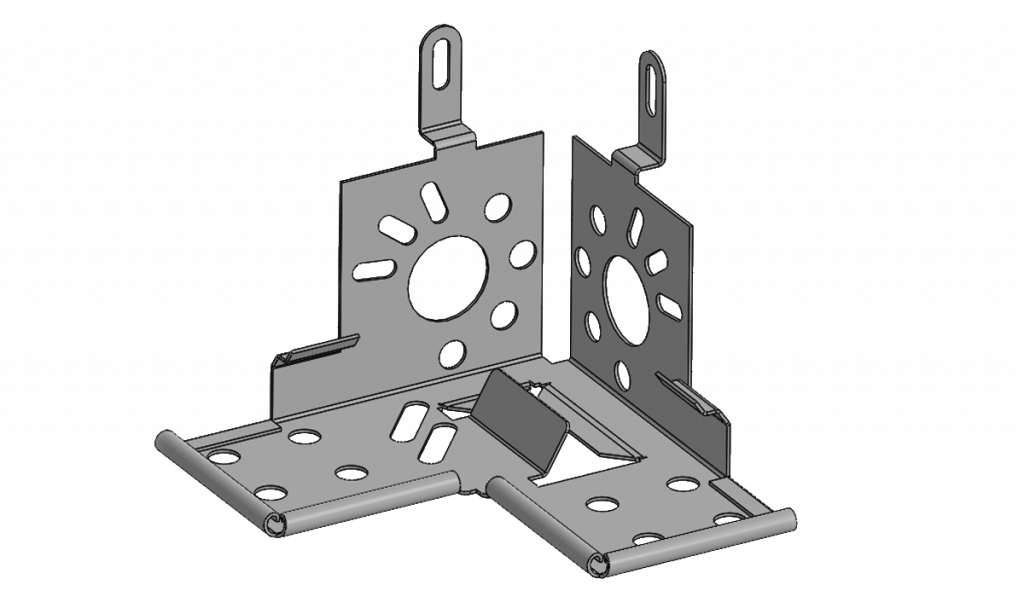

- Mould and Die Set Drafting Services – Comprehensive 2D layouts for core, cavity, and base plates

- Mould and Die Set Detailing Services – Focused detailing on inserts, sliders, cooling systems, and ejector pin

- Mould and Die Set Drawing Services – Complete production-ready documentation packages

- Injection Mould Die Design Drafting – Specialized drafting for thermoplastic and thermoset mould designs

- Mould Modeling and Modelling Services – 3D representation of complex geometries for visualization and simulation

- Mould Design Documentation – Structured output that supports quality inspection, tool setup, and maintenance

Each of these services plays a specific role in ensuring that the mould functions correctly from the very first shot to the final cycle.

Benefits of Choosing Expert Mould Drafting Services

Minimized Design Errors

Expert drafters anticipate and address potential conflicts in the early stages of development.

Improved Communication

Detailed, standardized drawings enhance coordination between designers, manufacturers, and clients.

Faster Time to Market

Accurate drafts reduce revision cycles, streamline tool-making, and enable quicker production starts.

Cost Efficiency

By minimizing rework, scrap, and trial tooling, companies save both time and material costs.

Long-Term Tooling Performance

Accurate drafting leads to well-aligned mould components that perform consistently over time.

In a manufacturing environment where precision, speed, and quality are non-negotiable, mould drafting services provide the framework for success. From ensuring dimensional accuracy to guiding complex tool assembly, these services are fundamental to every stage of mould production. By integrating cutting-edge software with engineering expertise, they transform ideas into tangible, error-free outcomes.

At As Industries, we take pride in offering expert mould drafting solutions that meet global quality standards while addressing the unique needs of each client. Our dedication to design accuracy ensures your moulds are not only efficient and reliable—but also ready to meet the demands of high-performance manufacturing.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.