Understanding the Key Benefits of Mechanical Modeling Services for Engineers

Mechanical Modeling Services, which use sophisticated software and tools to create precise digital representations of mechanical systems, have revolutionized the way engineers approach product development and manufacturing. These services allow engineers to simulate, analyze, and refine designs before committing to physical prototypes, ensuring higher accuracy and more efficient project execution. In an era where speed, quality, and cost-effectiveness are paramount, mechanical modeling services provide a powerful solution to meet these challenges while enhancing collaboration, reducing errors, and optimizing overall design processes.

Reducing Design Errors and Enhancing Accuracy

One of the standout benefits of mechanical modeling services is their ability to significantly reduce design errors. Traditional design methods, which rely on 2D sketches or physical prototypes, often face challenges in ensuring precision, leading to costly revisions. Mechanical modeling services leverage advanced 3D modeling tools like SolidWorks, AutoCAD, and Autodesk Inventor to create highly accurate digital models that replicate the real-world behavior of components. Engineers can examine these models from every angle and test their functionality under various simulated conditions. By identifying potential issues early in the design process—such as material weaknesses, assembly conflicts, or design flaws—engineers can make adjustments before manufacturing begins, ultimately saving time and money by reducing the risk of costly mistakes.

Cost and Time Savings Through Virtual Prototyping

Virtual prototyping is another key benefit that comes with mechanical modeling services. Traditionally, creating prototypes was a time-consuming and expensive process that required significant resources, including materials, labor, and manufacturing facilities. By using mechanical modeling services, engineers can create digital prototypes that replicate the physical product, allowing them to test and evaluate designs virtually. This capability not only accelerates the development timeline but also eliminates the need for multiple physical prototypes, which can be particularly costly in complex projects. Furthermore, by conducting tests like stress simulations and thermal analysis on digital models, engineers can ensure the design's robustness and functionality without the need for physical testing, ultimately reducing development costs.

Improved Collaboration and Communication

Mechanical modeling services also foster improved collaboration and communication between engineering teams, manufacturers, and other stakeholders. In large-scale projects, such as infrastructure or industrial applications, coordination between various departments is crucial. Digital models act as a shared reference point, ensuring that all teams are working from the same blueprint. Engineers can collaborate seamlessly, make real-time updates, and share model revisions instantly, regardless of location. This level of synchronization minimizes misunderstandings, errors, and delays, ultimately leading to more cohesive and efficient project execution. Furthermore, with cloud-based tools and software, engineers can remotely access and modify models, enabling global collaboration and streamlining workflows across teams that may be geographically dispersed.

Accelerating Product Innovation

Mechanical modeling services significantly contribute to product innovation by allowing engineers to explore new concepts and configurations quickly. In the past, physical limitations often restricted engineers’ ability to experiment with unconventional or complex designs. Today, mechanical modeling services offer the flexibility to test a wide range of design alternatives, materials, and manufacturing techniques, all within the digital realm. Engineers can evaluate different variations of a design without the need for multiple physical iterations, accelerating the innovation process. This level of freedom opens up new possibilities for creative solutions, ensuring that engineers can push the boundaries of product design and deliver cutting-edge innovations that stand out in a competitive marketplace.

Seamless Integration with Other Engineering Disciplines

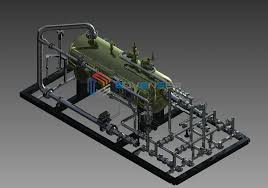

For large-scale projects, the integration of mechanical systems with other engineering disciplines is essential for ensuring that all elements work in harmony. Mechanical modeling services, particularly Mechanical BIM (Building Information Modeling) services, play a crucial role in this integration. Mechanical BIM modeling involves creating intelligent 3D models that incorporate detailed data about mechanical systems, such as HVAC, plumbing, and electrical components. These models are then integrated with architectural and structural models to ensure seamless coordination between all aspects of the design. This holistic approach minimizes conflicts, reduces the risk of errors during construction, and optimizes the overall efficiency of the project. Whether it's a commercial building, industrial facility, or infrastructure project, the ability to integrate mechanical systems with other engineering disciplines ensures smoother execution and long-term sustainability.

Fostering Sustainability and Resource Efficiency

In today’s engineering landscape, sustainability has become a critical factor in product design and development. Mechanical modeling services contribute to sustainability by helping engineers design more efficient and environmentally friendly products. Using advanced simulations, engineers can optimize designs for minimal resource usage, reduced waste, and improved energy efficiency. For example, digital models allow engineers to test the performance of energy-efficient components, simulate environmental conditions, and analyze the environmental impact of materials. By addressing these factors early in the design process, mechanical modeling services support the creation of products that are not only cost-effective but also environmentally responsible.

Support for Manufacturing and Assembly

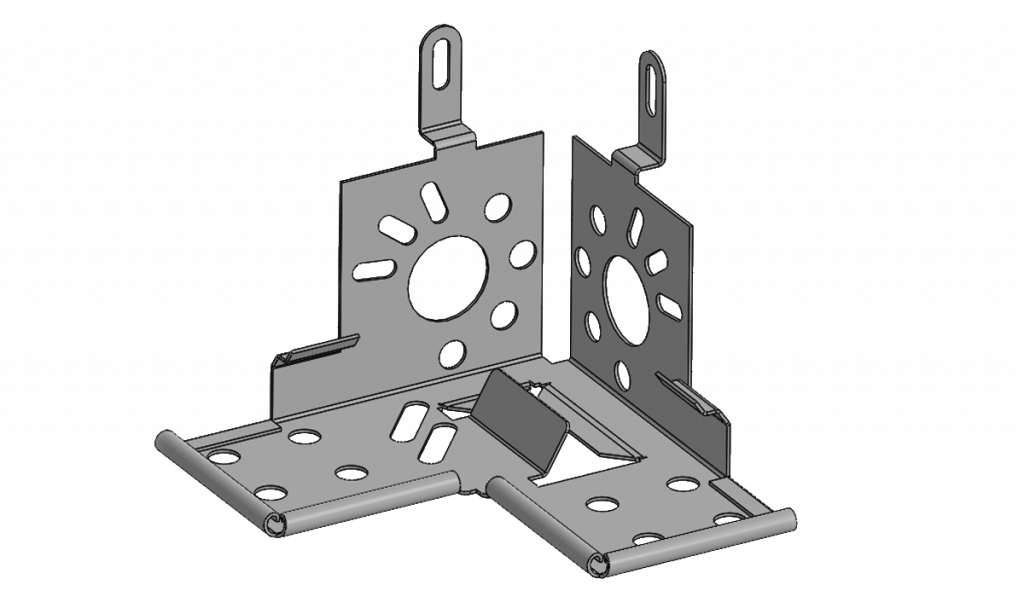

Finally, mechanical modeling services play a key role in supporting manufacturing and assembly processes. By providing detailed, precise models, engineers can ensure that all components are designed for manufacturability and ease of assembly. These models can include annotations, dimensions, and material specifications that guide the manufacturing process, reducing the likelihood of errors during production. Additionally, assembly simulations can be conducted to ensure that components fit together properly and can be assembled efficiently. This level of preparation ensures that the transition from design to production is smooth, minimizing delays and optimizing manufacturing workflows.

Mechanical modeling services are indispensable tools for modern engineers, offering a wealth of benefits that enhance the efficiency, accuracy, and innovation of product design. From reducing design errors and cutting costs to fostering better collaboration and accelerating product innovation, these services help engineers tackle the challenges of today’s fast-paced, complex engineering projects. By integrating mechanical modeling into their workflows, engineers can streamline the entire design-to-production process, deliver high-quality products, and stay competitive in an ever-evolving marketplace. At As Industries, we are committed to providing top-tier mechanical modeling services that support engineers in every phase of the design process, ensuring efficient and cost-effective solutions that drive long-term success.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.