What Differentiates Precast Shop Drawings from Regular Concrete Drawings?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

Precast concrete has changed the way construction happens in modern times; it moves elements of construction from the site, to the factory. Yet, many construction professionals treat precast drawings as just another version of regular concrete drawings, which causes delays and mistakes during the processes of fabrication, transportation, and erection. Precast drawings are structural drawings that differ from regular concrete drawings in their intent, choice of detailing, and intended audience. Regular concrete drawings indicate how work can be done on site, including general layout and reinforcing information. Precast shop drawings are product documents intended for off-site construction, including information the precaster will need to produce the product including, but not limited to; lifting insert locations and sequencing for delivery and erection. Precast shop drawings do not simply state what needs to be built, they indicate how and when it will be built. In this blog, we will explain what makes precast shop drawings different from regular concrete drawings and why that matters. We will examine every layer that exists separating precast documents from regular documents, from layout philosophy, to fabrication data, to logistics coordination.

Core Differences

A. Fabrication Intent vs Site-Centric Thinking

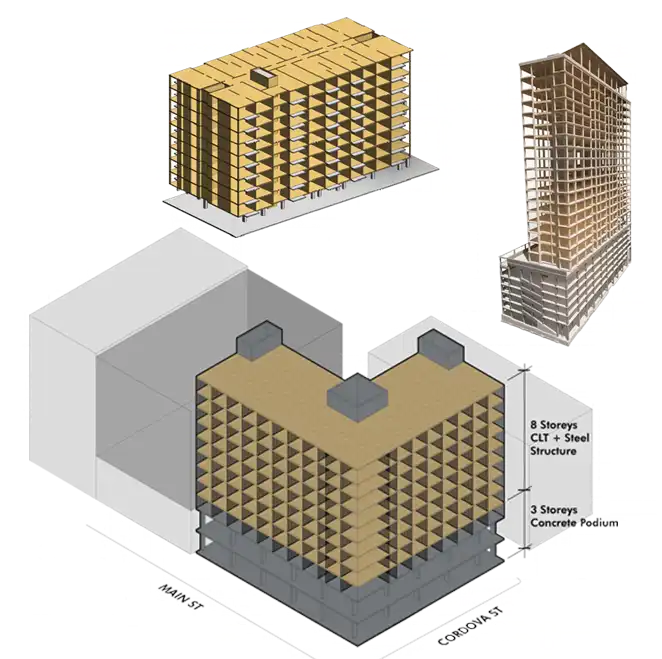

Traditional concrete drawings are predominantly in-situ and constructed with in situ methodologies in mind. In situ design assumes a site prepared for pouring, measurements by hand, and changes being made in the field. Precast Shop Drawings Services apply an offsite-first design philosophy. Every dimension, every joint, every inset is calculated for factory fabrication.

This change of origin changes the whole drafting approach. Standard drawings are usually for site engineers. Precast drawings get prepared for the manufacturing group, crane operator, and logistics group.

B. Sequence Matters More in Precast

In precast work, sequencing is usually more important than standard reinforcement layouts or rebar distributions. Drawings should show the sequence of casting, lifting direction, handling points, and delivery arrangements. In Precast Concrete Shop Drawings Services, these are not negotiable facets, they are central.

In contrast, normal concrete drawings make sequencing flexible and often leave site sequencing to site managers. Precast drawings lock that logic in from the beginning.

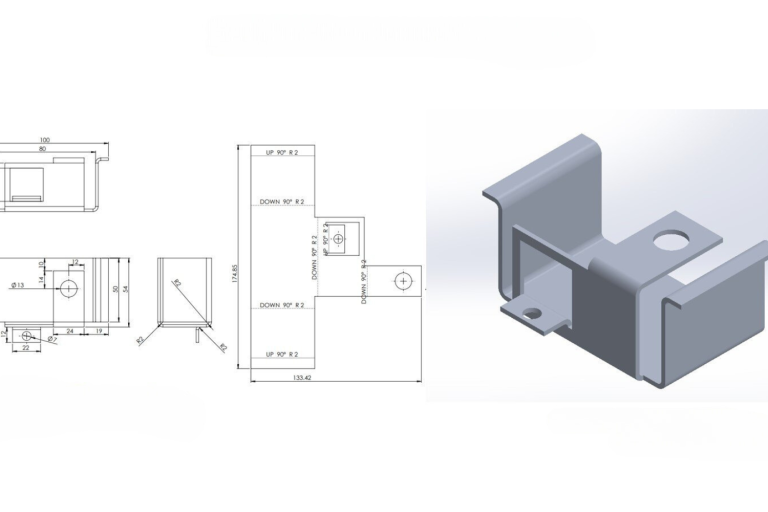

C. Embedded Components vs Rebar Details Alone

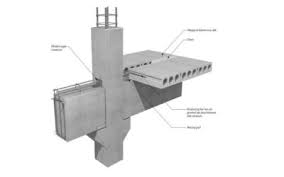

Standard drawing details highlight reinforcement bars, stirrups, and lap lengths; in precast-drawing (the embedded items such as connection plates, lifting anchors, or conduit sleeves are inherent detail-level drawings). This level of detail is necessary because, if you do not have offsite casting, you almost certainly cannot retrofit.

It is because of these distinctions that Panel Fabrication Drawings Services are essential for factory or construction environments altogether - the drawing is referencing the jig, the mould, and the pre-assembly station.

Detailing Focus and Layout Philosophy

A. Layout Design vs Element-Specific Logic

Typical concrete drawings usually include layout-wide details. Concrete floor plans, slab reinforcements, and column footings schedules are at best. Precast concrete drawings provide typical information on each modular precast element (wall panels, beams, columns) and all individual casting requirements.

Wall Panels Detailing Services would only describe each individual unit, and provide dimensions for a single wall slab, noting dimensional tolerances, lift hook locations, drainage slopes, or insulation fills, where applicable. However, a standard drawing would show the same features on their concrete panel plan in a single composite plan.

B. Factory Readiness and Assembly Suitability

The drawings will often be required to convey clear and concise guidelines for precast fabrication. During the site erection process, the interlocking panels will all fit together even if they are out millimeters. Precast Beam Detailing Services will include design considerations for deflection tolerances, camber tolerances, as well as tie positions. These specific elements do not typically get included or referenced in the typical concrete beam layouts.

More specifically because regular drawings include typical (and generic) views, the precast documentation can include isometric views or 3D exploded layouts that show every connection in the specific fabrication order to help the prefabrication team stay organized.

C. Handling and Lifting Considerations

This is where precast designs really differ from more "traditional" concrete methods. Each panel or beam drafted through Precast Concrete Shop Drawings Services must consider transportation layout and lifting orientation.

This leads to unique callouts like:

●Center of gravity markings

●Rigging hook insert positions

●Rotation instructions

●Tagging sequences for on-site assembly

These annotations don’t exist in typical concrete construction plans.

Communication Purpose

A. Site Engineers vs Production Teams

Normal concrete drawings are normally written for general site understanding--to allow civil engineers, masons, and inspection agents to picture what will be built. Precast drawings, on the other hand, are for production staff, and transport managers and crane drivers. The output from Precast Shop Drawings Services includes terms of fabrication dimensions, rigging diagrams, and cast phase references. These documents are significantly more specialized.

B. Integration With Vendor Systems

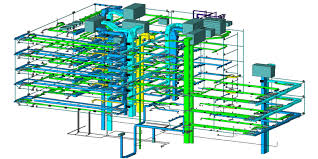

Precast shop drawings are required to coordinate with the inventories and processes of mould makers, steel cage suppliers, and concrete yard workers. A discrepancy between panel shop drawings and mould capacity can upset weeks of planning.

Specifically, Panel Fabrication Drawings Services are empowering service providers that connect design consultants with casting yards while also preparing the fabrication for action.

C. QA/QC and Inspection Workflows

A significant user of precast shop documents is the QA/QC group. All drawings assist in confirming dimensions at the pre-pour and post-cast, while regular drawings primarily support inspections post cast, often through visual or destructive testing.

This change in timing provides improved reliability of documents and significantly less stoppage of work.

Drawing Content and Complexity

A. Embedded Data Requirements

Precast drawings tend to contain more layers of instructions: weight estimates, insert types, projection allowances, and weld plate tags. Regular concrete drawings do not have this much detail because in many cases the elements are poured on site as a monolithic structure. In essence, precast concrete shop drawings are really a hybrid: part design and part production plan.

B. Tolerance Annotations and Checks

Tolerances drive the reliability of precast installation. Whether it's a beam seating detail or wall-to-slab overlap zone, the allowable margin must be identified.

Detailed Precast Beam Detailing Services will allow for tolerances related to standards including allowable distances between anchors, level of embeds and depth of projections that would likely not apply to conventional concrete detailing.

C. Logistics-Oriented Callouts

Precast Shop Drawings Services has to serve transportation logistics. Drawings often show shipping configurations, flatbed layouts and load sequence notes.

Wall Panels Detailing Services often refer to panel tag indices, matching truckloads. In this way the documentation happens in real time as part of the project.

Workflow Timing and Dependency

A. Early Design Finalization

Precast drawings need to be finalized far ahead of "conventional" drawings. Since precast fabrication occurs before the structure is built, there are very few opportunities for late design changes. It will require earlier approvals, an elongated lead planning time and a separate drawing approval process.

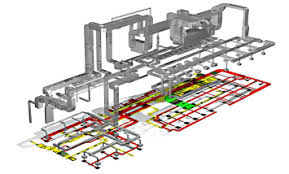

B. Cross-Disciplinary Coordination

In contrast to normal detailing, precast design must also consider the location of mechanical sleeves, electrical cutouts, and insulation zones. Unlike general concrete detailing, Panel Fabrication Drawings Services advertise MEP references from the beginning in a single service.

These services combine structure and infrastructure in a way concrete detailing seldom addresses.

C. Installation Dependency

Each precast panel or beam is a smaller part of a larger picture. Drawings must incorporate this modularity. Making a mistake in one panel drawing can affect two or more elevation erection operations.

In this case, Precast Concrete Shop Drawings Services includes an element of dimensional logic, above and beyond typical placement details.

Risk Exposure and Mitigation

A. Elimination of Rework Margins

Precast drawings have a unique degree of accountability. Because it can't be done on site, modifications to factory-made panels are examined much more thoroughly than any other type of drawing. Once an error is cast, the mistake is nearly permanent. Precast Beam Detailing Services will often incorporate checking grids, and referencing casting levels in order to prevent problems during fabrication.

B. Modular Fabrication Dependencies

A missing sleeve or embed on-site in a traditional casting could possibly be resolved with remediation. In precast, that same mistake would render an entire piece of precast unusable.

For that reason, shop drawings are basically manufacturing blueprints with revision control and batch identifiers.

C. Error Propagation Risk

Small variations can be localized in the world of conventional cast-in-place concrete construction. However, in the precast, the drawings rely on one another. The way one slab is installed can impact the way others are installed. As such, precast shop drawing services require a hierarchy of drawings such as master coordination plans, erection sequence drawings or field-verified information.

Final Thoughts

The difference between standard concrete drawings and precast shop drawings is not merely a difference in format or file type. It's about intent. One is outward-facing to the site, while the other is inward-facing to the factory and with an eye toward crane delivery.

When using Wall Panels Detailing Services, you engage a different level of project planning. These are not mere drawings; they are engineered with intent to help facilitate the offsite building revolution.

As such, Precast Shop Drawings Services embody the design hub of a method of construction that is ultimately defined by accuracy, coordination, and timing of delivery. They exemplify the newest evolution of making drawings that do not just describe, they move a project along, from the factory floor to the final fix.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.