Launch apps instantly. Claim $200 credits on DigitalOcean

Launch apps instantly. Claim $200 credits on DigitalOcean

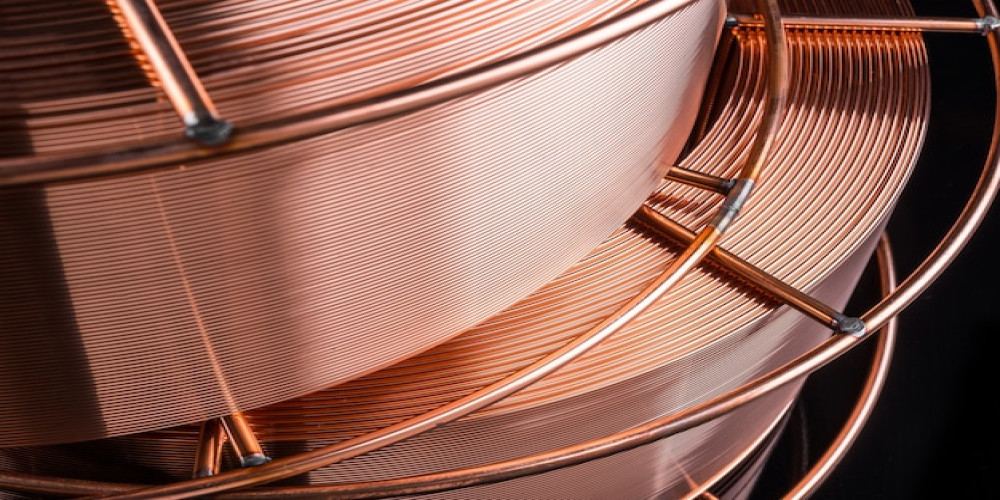

Exploring the Wonders of Bimetallic Strips Copper and Aluminium

Written by Johnx » Updated on: January 03rd, 2024

In the realm of materials engineering, bimetallic strips copper aluminium stand out as ingenious devices that harness the unique properties of two distinct metals. Among these combinations, the marriage of copper and aluminium in bimetallic strips has found widespread applications due to the complementary attributes of these metals. In this article, we will delve into the fascinating world of bimetallic strips, focusing on the dynamic interplay between copper and aluminium, and the diverse applications that arise from their collaboration.

Understanding Bimetallic Strips:

A bimetallic strip is a composite material made by bonding two different metals with different coefficients of thermal expansion. Copper and aluminium, when combined in a bimetallic strip, create a structure that responds to changes in temperature by bending or curving. This unique property makes bimetallic strips invaluable in various applications, ranging from thermostats to electrical devices.

Thermal Expansion Dynamics:

Copper and aluminium have different rates of thermal expansion. When exposed to changes in temperature, the bimetallic strip undergoes unequal expansion or contraction, causing it to bend.

This phenomenon is a result of the metals' varying responses to temperature fluctuations, with one metal expanding or contracting more than the other.

Applications in Thermostats:

Bimetallic strips are commonly used in thermostats to regulate temperature. As the temperature changes, the strip bends, activating or deactivating a switch that controls the heating or cooling system.

The precision and reliability of bimetallic strips make them integral components in temperature-sensitive devices.

Circuit Breakers and Switches:

The bending action of bimetallic strips is harnessed in electrical devices such as circuit breakers and switches.

As the strip bends due to temperature changes or electrical current, it can break or complete a circuit, providing a mechanism for controlling electrical flow.

Fire Safety Devices:

Bimetallic strips are utilized in fire safety devices, such as fire sprinkler heads. Changes in temperature, indicative of a potential fire, trigger the bending action of the strip, releasing the flow of water to suppress the fire.

Advantages of Copper-Aluminium Bimetallic Strips:

Optimal Balance of Properties:

Copper offers excellent electrical conductivity, while aluminium is prized for its lightweight and corrosion-resistant properties. The combination strikes a balance, providing a versatile material with a range of applications.

Cost-Effectiveness:

Aluminium is often more cost-effective than copper. By strategically combining the two metals, manufacturers can achieve desired properties while keeping costs in check.

Reduced Thermal Inertia:

The use of aluminium in the bimetallic strip reduces thermal inertia, enabling quicker response to temperature changes.

This characteristic is particularly advantageous in applications where rapid and accurate temperature sensing is crucial.

Conclusion:

The collaboration between copper and aluminium in bimetallic strips exemplifies the harmony achieved by combining materials with complementary properties. From regulating temperature in thermostats to enhancing safety in electrical devices, the versatility of bimetallic strips makes them indispensable in various industries. As technology continues to advance, the dynamic interplay between metals like copper and aluminium serves as a testament to the ingenuity of materials engineering, unlocking new possibilities for innovation across different fields.

Copyright © 2024 IndiBlogHub.com Hosted on Digital Ocean

Post a Comment

To leave a comment, please Login or Register