Launch apps instantly. Claim $200 credits on DigitalOcean

Launch apps instantly. Claim $200 credits on DigitalOcean

Pipe Fitting Sizes: A Comprehensive Chart

Written by Archana Shah » Updated on: January 03rd, 2024

Understanding Pipe Fitting Size Chart for Easy Selection

Pipes and fittings are the arteries of any plumbing or industrial system, and their seamless integration relies heavily on accurate sizing. Whether it’s for household plumbing, industrial applications, or construction projects, having a clear understanding of pipe fitting sizes is crucial. To simplify this process, we’ve compiled an extensive pipe fitting size chart along with essential insights to aid in your selection process.

Why Pipe Fitting Sizes Matter

Pipe fittings are essential components in plumbing and piping systems, serving the critical role of connecting, redirecting, and controlling the flow of fluids. These fittings enable the interconnection of pipes, accommodating various shapes, sizes, and materials to facilitate the efficient functioning of diverse systems, from residential plumbing to industrial pipelines.

At their core, pipe fittings provide the necessary flexibility to adapt to different pipe configurations and system requirements. They come in an extensive array of shapes, sizes, and materials to suit specific applications and operating conditions. Common materials include metals like steel, copper, and brass, as well as plastics such as PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride). The choice of material depends on factors like fluid compatibility, pressure, temperature, and environmental conditions.

Pipe fittings encompass a wide range of types, each designed for specific functions within a piping system. Some of the most prevalent fittings include elbows, tees, couplings, unions, reducers, and valves. Elbows allow directional changes in piping systems, coming in various angles (like 45 or 90 degrees) to redirect flow. Tees enable branching of pipelines into multiple directions. Couplings connect two pipes of the same diameter, while unions facilitate the disconnection and reconnection of pipes for maintenance purposes.

Reducers are critical in transitioning between pipes of different sizes, allowing for the smooth flow of fluids despite variations in diameter. Valves, though distinct from traditional fittings, control the flow within a system, regulating or stopping fluid movement as required.

The installation process of pipe fittings demands precision and adherence to industry standards. Properly fitting and sealing the joints prevent leaks and ensure the system's integrity. Techniques like soldering, threading, welding, or using adhesives and compression fittings are employed based on the material and type of fitting.

In residential plumbing, fittings play a pivotal role in connecting fixtures, pipes, and appliances, ensuring a well-functioning water supply and drainage system. Couplings and elbows are commonly used to navigate corners and connect different sections of pipes, while valves provide control over water flow.

Industrial applications heavily rely on pipe fittings to manage complex systems conveying various fluids, gases, or chemicals. The choice of fittings in these settings is critical, considering factors such as pressure, temperature, and the nature of the substances being transported. Specialized fittings like flanges and expansion joints are used to accommodate thermal expansion, contraction, and vibration in industrial environments.

Regular maintenance of pipe fittings is crucial to prevent corrosion, leaks, or failures that could compromise the system's efficiency and safety. Inspections for wear, corrosion, and proper sealing ensure optimal performance and longevity.

Moreover, advancements in fitting design and manufacturing have led to the development of innovative fittings, such as push-to-connect fittings, which streamline installation and minimize the need for specialized tools or skills. These fittings employ O-rings or gripping mechanisms to create reliable seals without requiring soldering, gluing, or threading.Pipe fittings serve the critical role of connecting, diverting, or controlling the flow within a piping system. Accurate sizing ensures leak-free connections, optimal flow rates, and overall system efficiency. Understanding the dimensions and compatibility of fittings is fundamental in achieving a properly functioning system.

The Basics of Pipe Fitting Sizes

Pipe fitting sizes are typically categorised by their diameter, either in nominal pipe size (NPS) or outside diameter (OD). The NPS represents the approximate inside diameter of the pipe, while the OD refers to the actual outside diameter.

Common Pipe Fitting Types

Elbows These fittings allow for directional changes in piping systems, typically available in various angles (90 degrees, 45 degrees, etc.).

Tees: Tees allow for a branch connection, enabling the flow in two directions perpendicular to the main pipe.

Reducers: Reducers assist in transitioning between pipes of different diameters, facilitating a smooth flow.

Couplings: Couplings are used to join two pipes of the same diameter, ensuring a secure connection.

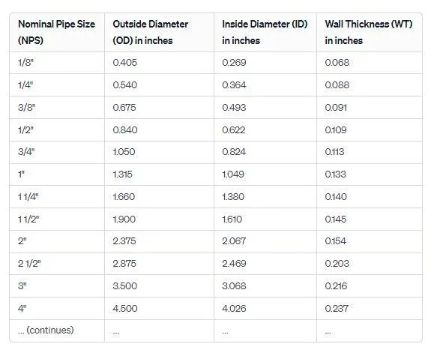

Pipe Fitting Size Chart in inches

Below is a comprehensive pipe fitting size chart that covers various common sizes and dimensions:

*Note: These dimensions are standard and may vary depending on material and specific fittings.*

Using the Pipe Fitting Size Chart

Identifying Fitting Sizes: Match the required nominal pipe size or outside diameter of the pipe with the appropriate fitting dimensions in the chart.

Understanding Wall Thickness: Consider the wall thickness when selecting fittings, especially in applications where pressure or corrosion resistance is a concern.

Material Compatibility: Ensure that the material of the fittings aligns with the material of the pipes for compatibility and longevity.

Application Specifics: Take into account factors like pressure ratings, temperature variations, and environmental conditions for suitable fittings.

Conclusion

A comprehensive pipe fitting size chart simplifies the selection process, enabling efficient and accurate fitting choices for various plumbing or industrial systems. Understanding the dimensions and types of fittings ensures seamless integration and functionality within any piping network.

Remember, while this chart provides a general overview, consulting industry standards, specific material specifications, and considering application requirements is crucial for precise and optimal fitting selections.

Armed with this knowledge and the provided chart, navigating the world of pipe fittings becomes a far more manageable task, facilitating smooth installations and reliable system operations.

Copyright © 2024 IndiBlogHub.com Hosted on Digital Ocean

Post a Comment

To leave a comment, please Login or Register