Launch apps instantly. Claim $200 credits on DigitalOcean

Launch apps instantly. Claim $200 credits on DigitalOcean

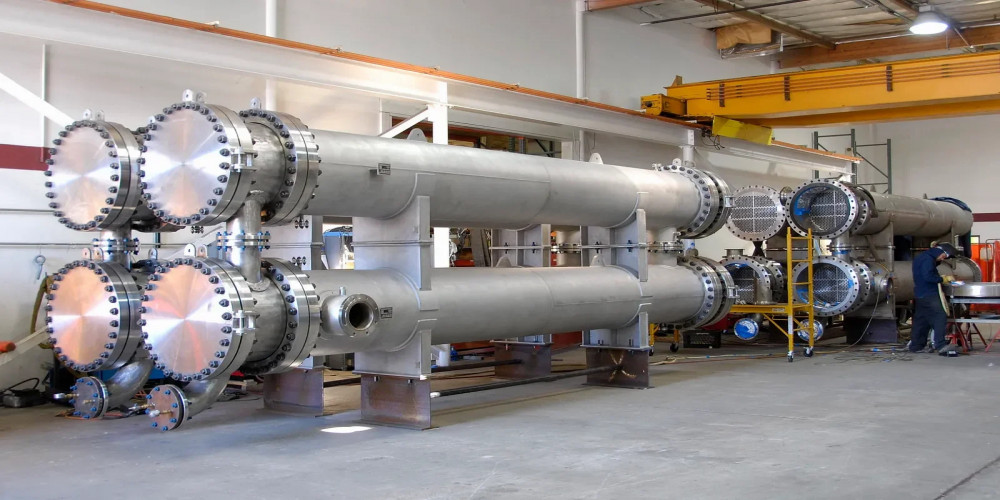

Unraveling the Intricate World of Heat Exchanger Parts

Written by Hermione » Updated on: February 17th, 2024

In the realm of thermal management and energy efficiency, heat exchangers have emerged as indispensable components in numerous industries. From power generation to refrigeration, chemical processing to HVAC systems, these ingenious devices play a pivotal role in transferring thermal energy between two or more fluids, ensuring optimal performance and energy conservation. At the heart of every heat exchanger lies an intricate assembly of meticulously designed parts, each contributing to its overall functionality and efficiency. In this comprehensive article, we will explore the fascinating world of heat exchanger parts, unraveling their unique roles and significance.

The Core Components of Heat Exchangers

At the core of any heat exchanger lies a series of tubes or plates, designed to facilitate the transfer of heat between two distinct fluid streams. These core components are often crafted from highly conductive materials, such as copper, aluminum, or stainless steel, ensuring efficient heat transfer while withstanding the rigors of demanding operating conditions.

Tubes: In tubular heat exchangers, a network of tubes is arranged in a specific configuration, allowing hot and cold fluids to flow through alternating channels. The tube material, thickness, and surface area play crucial roles in determining the overall heat transfer rate.

Plates: Plate-type heat exchangers employ a series of corrugated or embossed plates stacked together, creating intricate flow channels for the two fluids. The plate material, surface pattern, and spacing between plates contribute to the exchanger's thermal performance.

Auxiliary Parts for Enhanced Efficiency

While the core components facilitate the primary heat transfer process, a multitude of auxiliary parts work in tandem to ensure optimal performance, durability, and ease of maintenance.

Baffles: These strategically placed components guide the fluid flow, increasing turbulence and promoting better heat transfer between the fluids and the heat transfer surface.

Header Boxes: Header boxes provide an inlet and outlet for the fluids, evenly distributing the flow across the heat transfer surface and minimizing pressure drops.

Gaskets and Seals: Gaskets and seals play a vital role in preventing fluid leakage, ensuring the integrity of the heat exchanger and minimizing the risk of contamination or environmental hazards.

Materials and Coatings for Demanding Environments

The selection of materials and coatings for heat exchanger parts is a crucial aspect, as these components often operate in harsh environments with extreme temperatures, corrosive fluids, or high pressures.

Corrosion-Resistant Materials: Stainless steel, titanium, and specialized alloys are frequently used in heat exchangers exposed to corrosive fluids or aggressive operating conditions, ensuring long-term durability and reliable performance.

Coatings and Surface Treatments: In some cases, heat exchanger parts may be coated with specialized materials or undergo surface treatments to enhance their resistance to fouling, corrosion, or erosion, further extending their service life.

Maintenance and Replacement of Heat Exchanger Parts

Like any complex system, heat exchangers require regular maintenance and occasional replacement of worn or damaged parts to maintain peak efficiency and prevent costly breakdowns.

Cleaning and Descaling: Over time, fouling and scale buildup can occur on heat transfer surfaces, impeding heat transfer and reducing overall efficiency. Regular cleaning and descaling procedures are essential to restore optimal performance.

Part Replacement: Due to the high temperatures, pressures, and corrosive environments in which heat exchangers operate, certain parts may eventually succumb to wear and tear, necessitating replacement to prevent catastrophic failures.

Conclusion

The world of heat exchanger parts is a testament to the ingenuity and precision of engineering design. From the core components that facilitate heat transfer to the auxiliary parts that enhance efficiency and durability, each element plays a crucial role in the overall performance of these remarkable devices. By understanding the intricate interplay of these parts and their unique functions, industries can optimize their thermal management processes, reduce energy consumption, and minimize environmental impact. As technology continues to evolve, the design and manufacturing of heat exchanger parts will undoubtedly keep pace, pushing the boundaries of efficiency, reliability, and sustainability.

Copyright © 2024 IndiBlogHub.com Hosted on Digital Ocean

Post a Comment

To leave a comment, please Login or Register